MotorAnalyzer1

The entry-level device for your motor service

Compact design and a wide range of applications for troubleshooting in windings that are not live are the distinguishing features of this tester.

Ten reliable tests and test methods are built in. Due to its integrated rechargeable battery, tests can also be performed off-grid, without a power connection. It is a versatile tool for electrical engineering, motor repair, maintenance and servicing.

Product consultant

Key-Facts

10 test methods in 1 device

- Universal stator-, armature-, motor- and transformer-tester

- 10 test methods

- autotest

- surge voltage

- resistance

- high voltage DC

- polarization index

- insulation resistance

- PE/GB-resistance

- “neutral zone”-adjustment for DC motors

- rotary field on stator or motor

- winding fault location with a test probe for stator and armature

- rotating switch for quick test method selection

- automatic switchover between the three motor connection cables

- built-in test result log

- data transfer to PC via RS-232 or USB interface

- easy-to-read large-screen graphics display

- off-grid battery operation with battery status indicator

- lightweight

- Windows®-software for importing test results and printing test reports

Description

The versatile instrument.

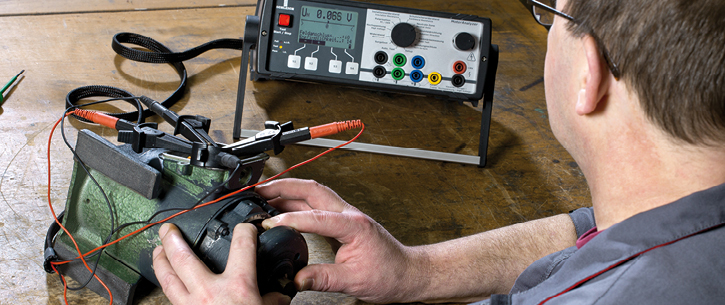

Our MotorAnalyzer1 is a universal tester for electric motors and winding goods. It unites ten different test methods in one user-friendly and portable device. The combination of test methods, its ultra-compact design and the battery powered operation make the MotorAnalyzer1 the perfect tool for on-site use – particularly in difficult mounting locations.

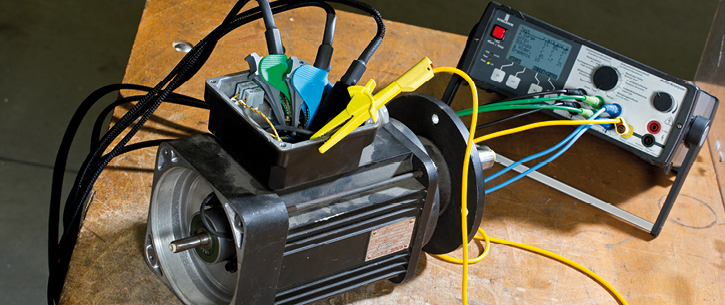

To test an electric motor, the three winding leads and the motor housing are wired to the tester. The surge voltage and resistance tests are set in motion automatically. Subsequently, the motor is submitted to a high-voltage test in order to assess the quality of the motor in a fast and accurate manner.

MotorAnalyzer1 was designed for both in-house and on-site use. Off-grid battery mode lets you test electric motors (e.g. on a crane) accurately even in complex mounting locations. With MotorAnalyzer1 the user will have the ability to make a definitive GO/NOGO-assessment using all built-in test methods and advanced software diagnostics with superior visual support on-screen.

Technology

Technical specifications overview.

Power supply

- built-in battery

- external charger

Autotest

- automatic stator-, motor- and winding testing

- automated fault detection

Surge voltage

- automatic and manual surge voltage tests

- 1-, 2- and 3-phase

- Visual representation of the surge wave

- automated analysis

Resistance

- 1-, 2- and 3-phase

- Imbalance analysis

- precision 4-wire measurement

- Temperature compensation

Insulation resistance

- 0 – 4.000 V

- up to 100 GΩ

- manually adjustable

- auto-programmable

- in accordance with VDE 0701

Polarization index

- 0 – 4.000 V

- PI-measurement

- DAR-measurement

- automated measurement cycle

High voltage DC

- 0 – 4.000 V

- manually adjustable

- auto-programmable

- Voltage measurement in stages

PE/GB-resistance

- in accordance with VDE 0701

“Neutral zone” in DC motors

- visual indication of the deviation of the ideal brush adjustment via a bar graph

- acoustic indication of the deviation of the ideal brush adjustment via acoustic signal

Rotary field

- stator-rotary field measurement

- motor-rotary field measurement

Winding fault location

- winding fault location with a test probe

- visual indication of the winding fault location via a bar graph

- acoustic indication of the winding fault location via acoustic signal

⇒ Find more details under Downloads.

Applications

Motor inspection in the workshop.

A useful test method is the autotest. It shows an overview of all test results in a single fully automatic test run.

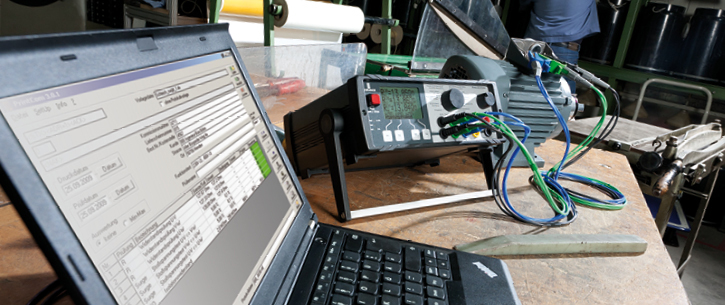

Testing of a motor and transfer of test results to a PC.

Alltest data is saved on the PC and subsequently printed.

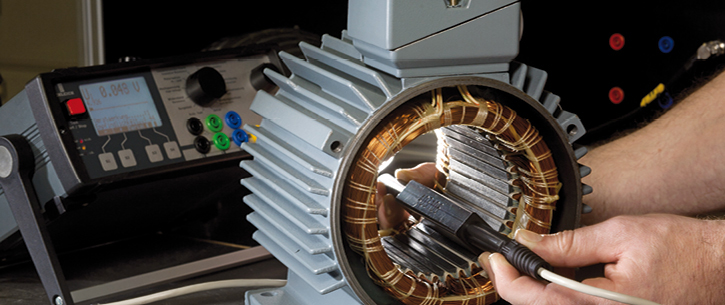

Finding the turn-to-turn fault

Fault detection of a turn-to-turn fault.

The probe is used to test each slot.

If a turn-to-turn fault is present, a deviation has to be traceable in two slots, since the coil with a turn-to-turn fault leads through two slots.

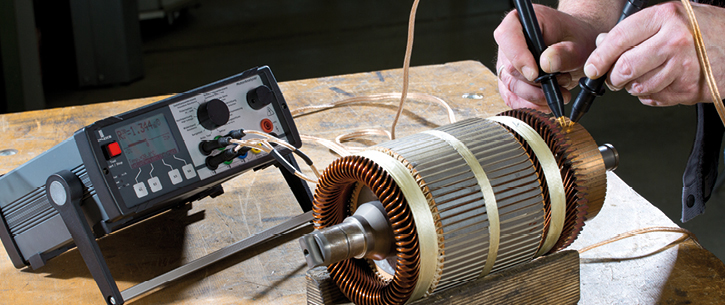

Turn-to-turn fault testing at a rotor

Resistance test at a rotor

Resistance test using two four-wire measurement probes.

Both test probes, each housing two measuring contacts, are pressed against two bars of the rotor. As the test probes are moved from bar to bar, each respective resistance measurement is detected.

High-voltage test DC.

High-voltage test at a motor between winding and frame or between single windings or to a temperature sensor.

Adjustment of the „neutral zone″.

“Neutral zone”-adjustment of a DC motor.

The brush bridge is rotated until the neutral zone is detected precisely. The MotorAnalyzer automatically displays the directional deviation indicating in which direction the operator must turn the carbon brush.

Accessories

PrintCom 7

PC-Software for storing and printing test results- transfer test results to a PC

- storing the test results in EXCEL file

- printing test results

Kelvin Clamps

High-precision resistance measurement even for smallest resistances- condition for high-precise resistance measurements

- solid industrial quality

- 3 different sizes

Motor Terminal Plugs

Test plugs for contacting motor terminal boards- induction motor test plugs / motor terminal board plugs

- quick contact for 6, 8 or 9 bolts

- for different motor terminal board sizes

- for threaded bolts M4, M5, M6, M8 and M10

- without, with 1 or 2 motor grounding tips

- super simple test lead connection

- 4 patents pending

Safety Barriers

For securing the testing area- mobile workplace protection

- with integrated emergency stop, warning lights

- built-in 2-hand start

For further information please do not hesitate to contact our technical sales under:

- +49 2372 901 25 40

- Email request

print preview

Product comparison

| type of tester |

| surge test |

| resistance |

| Induktivitäts-Kapazitätsprüfung |

| PE/GB |

| insulation |

| polarization index |

| high voltage AC |

| high voltage DC |

| partial discharge |

| function AC 1-phase |

| function AC 3-phase |

| sense of rotation |

| test terminals |

| test cover |

| automation |

| database |

| test plans |

| test results |

| communication |

| test report print-out |

| label print-out |

| scanner port |

| password protection |

| user management |

| operating system |

| display |

| battery mode |

| delivery |

|

|

|

|

|

|

|

|

|

|

|

| MTC2 R7 | MotorAnalyzer1 | MotorAnalyzer2 R2 | MTC2 | MTC3 | VoltageAnalyzer | GLP3-M | EncoderAnalyzer | Dynamic MotorAnalyzer | PortaTest | Winding Machines |

|

THE surge tester · normative partial discharge · resistance · 4 wire measurement · Windows 10|11® · test report · PDF printing · network … |

motor Service · repairs · troubleshooting · maintenance · servicing · battery operation · PC software … |

multitool · 15 test methods · surge voltage 3 kV · resistance · inductance · capacitance · motor service · repair · fault detection · maintenance · battery mode · PC software … |

THE surge tester – up to 50 kV – plus normative partial discharge – resistance – 4-wire measurement – Windows10® – test protocol – PDF printing – network … |

Uncompromising ALL-IN-1 winding test for production · for all standard and special motors · for automotive drives · for coils of all kinds · automation · in-line partial discharge testing – worldwide networking · central data storage … |

high-precision test probe – direct surge voltage measurement at the winding – partial discharge – passive / active microwave antenna – up to 6 kV … |

modular ALL-IN-1 engine test system · no limits · customer specific · VDE/EN/UL/IEC … · production · automation · global networking · databases · statistics · data import/export · Windows® · complex systems … |

encoder and resolver testing/adjustment · encoder signal analysis · encoder power supply: 3 – 30 V · interface: HIPERFACE – EnDat – SSI – BiSS · BEMF measurement · repair · motor service · encoder production · servo motor production … |

online monitoring · fault analysis on the running motor · for mains and frequency converters · over 100 measured values · speed · torque · efficiency · unique oscilloscope · data recorder · trend analysis · battery operation · outdoor … |

insulation oil testing ⋅ fully automatic ⋅ dielectric strength ⋅ mobile ⋅ portable ⋅ on-site testing ⋅ laboratory testing ⋅ test voltages: 60 kV – 80 kV – 100 kV ⋅ various electrodes ⋅ integrated international test standards … |

coil winding machines for electric motors · for repair · for motor production · standard machines · special solutions … |

| read more | read more | read more | read more | read more | read more | read more | read more | read more | read more | read more |

|

surge testers winding testers |

winding testers motor & winding testers ALL-IN-1 |

surge testers winding testers motor & winding testers ALL-IN-1 |

surge testers winding testers |

surge testers winding testers |

— | electric motor testers ALL-IN-1 | encoder/resolver testers | electric motor testers ALL-IN-1 | insulating oil testers | winding machines |

|

0–6 kV 0–12 kV 0–15 kV |

— | 0–3 kV |

0–6 kV 0–12 kV 0–15 kV 0–25 kV 0–30 kV 0–40 kV 0–50 kV |

0–6 kV 0–15 kV |

0–6 kV | 0–6 kV | — | — | — | — |

| 4-wire measurement | 4-wire measurement | 4-wire measurement | 4-wire measurement | 4-wire measurement | — | 4-wire measurement | — | — | — | — |

|

nein ja |

— | — | — | — | — | — | — | — | — | — |

| — | — | — | — |

1–10 A˜ 6/12 Veff 1–30 A˜ 6/12 Veff |

— |

1–10 A˜ 6/12 Veff 1–30 A˜ 6/12 Veff custom |

— | — | — | — |

| Vmax like surge test | 0–3 kV ˭ | 0–6 kV ˭ | Vmax like surge test | Vmax like surge test | — |

0–1 kV ˭ max. 250 GΩ custom |

— | — | — | — |

| Vmax like surge test | Vmax like insulation test | Vmax like insulation test | Vmax like surge test | Vmax like surge test | — | — | — | — | — | — |

| 0–6 kV˜ max. 100 mA | — | — | 0–6 kV˜ max. 100 mA |

0–3 kV˜ max. 100 mA 0–6 kV˜ max. 100 mA 0–6 kV˜ max. 200 mA 0–6 kV˜ max. 1 A custom |

— |

0–3 kV˜ max. 100 mA 0–6 kV˜ max. 100 mA 0–6 kV˜ max. 200 mA custom |

— | — | — | — |

| 0–4 kV ˭ | 0–6 kV ˭ | — | custom | — | — | — | — | |||

| in case of surge test | — | — | in case of surge test |

in case of surge test in case of high voltage test AC in case of surge voltage and high voltage |

in case of surge test |

in case of surge test in case of high voltage test AC in case of surge voltage and high voltage |

— | — | — | — |

| — | — | — | — | — | — | according to your requirements | — | — | — | — |

| — | — | — | — | — | — | according to your requirements | — | according to your requirements | — | — |

| yes | yes | yes | yes | yes | — | yes | — | — | — | — |

|

T1, T2, T3, frame T1, T2, T3, Y, frame K1, K2, frame |

T1, T2, T3, frame | T1, T2, T3, frame |

T1, T2, T3, frame T1, T2, T3, Y, frame K1, K2, frame |

T1, T2, T3, frame T1, T2, T3, Y, frame 3, 6, 9, 12, 15, 18, ..., frame |

T1, T2, T3 |

L1, L2, L3, N, PE made to your specifications |

— | — | — | — |

| possible | — | — | possible | possible | — | possible | — | — | — | — |

|

with digital I/O with RS232 via SCHLEICH communication protocol with LAN via SCHLEICH communication protocol |

— | — |

with digital I/O with RS232 via SCHLEICH communication protocol with LAN via SCHLEICH communication protocol |

with digital I/O with RS232 via SCHLEICH communication protocol with LAN via SCHLEICH communication protocol with LAN via TCP/IP Socket Communication with PROFIBUS with PROFINET with EtherCAT with DeviceNet made to your specifications |

— |

with digital I/O with RS232 via SCHLEICH communication protocol with LAN via SCHLEICH communication protocol with LAN via SCPI commands with PROFIBUS with PROFINET with EtherCAT with CANopen with CAN Automotive with DeviceNet made to your specifications |

— | — | — | — |

|

ACCESS SQL |

— | — |

ACCESS SQL |

ACCESS SQL |

— |

ACCESS SQL ORACLE |

— | — | — | — |

|

stored in the tester stored in the tester and network import from PC, PLC, MES, ... |

— | — |

stored in the tester stored in the tester and network import from PC, PLC, MES, ... |

stored in the tester stored in the tester and network import from PC, PLC, MES, ... |

— |

stored in the tester stored in the tester and network import from PC, PLC, MES, ... |

— | — | — | — |

|

cached in the tester or network transfer to PC, PLC, MES, ... |

cached in the tester | cached in the tester |

cached in the tester or network transfer to PC, PLC, MES, ... |

cached in the tester or network transfer to PC, PLC, MES, ... |

— |

cached in the tester cached in the tester or network transfer to PC, PLC, MES, ... |

— | — | — | — |

|

with ERP, MES, PLC, CAQ, ... via LAN, WWW, OPC, ... |

— | — |

with ERP, MES, PLC, CAQ, ... via LAN, WWW, OPC, ... |

with ERP, MES, PLC, CAQ, ... via LAN, WWW, OPC, ... |

— |

with ERP, MES, PLC, CAQ, ... via LAN, WWW, OPC, ... |

— | — | — | — |

| yes | yes - via PC-Software | yes - via PC-Software | yes | yes | — | yes | — | yes | — | — |

| yes | — | — | yes | yes | — | yes | — | — | — | — |

| yes | — | — | yes | yes | — | yes | — | — | — | — |

| yes | — | yes | yes | yes | — | yes | — | yes | — | — |

| yes | — | — | yes | yes | — | yes | — | yes | — | — |

| Windows 10 11®-PC in the tester | SCHLEICH embedded | SCHLEICH embedded | Windows 10®-PC in the tester | Windows 10®-19"-Industrial PC integrated | — | Windows 10®-19"-Industrial PC integrated | — | Windows 10®-PC in the tester | — | — |

| PC monitor of any size | LCD 120 x 80 | touch color LCD 480 x 272 | PC monitor of any size | PC monitor of any size | — | PC monitor of any size | — | — | — | — |

| — | yes | yes | — | — | — | — | — | yes | — | — |

| on stock | on stock | on stock | on stock | order-related manufacturing | order-related manufacturing | order-related manufacturing | order-related manufacturing | order-related manufacturing | order-related manufacturing | order-related manufacturing |

SCHLEICH is a leading manufacturer of electrical safety, functional, winding and electric motor testing technology.

SCHLEICH is a world-renowned company that focuses on the development of innovative products in the field of testing technology for electrical products of all kinds.

From A to Z - everywhere SCHLEICH testing technology is in use worldwide. Our customers come from over 50 countries and regions. Everything is developed and produced in Germany.

Quality work - Made in Germany.

2022 - SCHLEICH is awarded for the fifth time as TOP100-Innovator

2016 - SCHLEICH released the first VoltageAnalyzer for measuring the real voltage directly at the winding terminals

2012 - SCHLEICH is awarded as TOP100-Innovator for the first time

2005 - SCHLEICH released the first stator tester with partial discharge test

1995 - SCHLEICH integrates touch-displays into testing devices as a world leader

1990 - SCHLEICH released the first safety and function tester with fully automatic integrated test terminal changeover

1987 - SCHLEICH released the first surge tester with PC-control under DOS and fully automatic integrated test terminal changeover

1985 - SCHLEICH released the first MotorAnalyzer

1982 - SCHLEICH focuses fully on electrical test engineering of electrical products

1952 - SCHLEICH is founded as a motor repair shop

Pioneering spirit, competence, curiosity, brand new technologies and innovations. This is what the 145-strong SCHLEICH team stands for - led by Martin & Jan-Philipp Lahrmann. Father & son. Your guarantors for long-term partnership.