Bonding Machines

Thermal bonding of windings and coils of any type

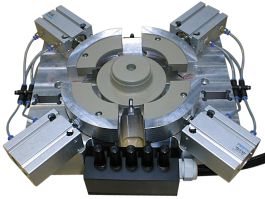

We implement your individually designed automatic thermal bonding machines according to your specifications. We offer manual individual or multiple workstations as well as fully automatic systems for line production or rotary switching tables.

SCHLEICH bonding systems allow for up to eight simultaneous, autonomous bonding processes.

Product consultant

Key-Facts

Reliable. Easily configurable. Reproducible. Highest precision.

- Current heating systems

- Electrical heating of coils

- DC-bonding machine

- AC-bonding machine for interconnected 3-phase windings

- Up to 100 kW

- Up to 2.500 A

- Up to 1.000 V

- Up to 250 A/mm2 and more – depending on the load capacity of the winding connector

- Different heating methods

- constant voltage

- constant current

- constant temperature

- temperature profil

- Bonding or impregnation of numerous coils in series- and parallel connection

- Standard- and high speed bonding with current densities up to 200 A/mm2

- Monitoring of temperature course during the bonding process

- Kelvin-resistance measurement (4W technology)

- Online temperature-monitoring

- Online connection clamps monitoring

- Dynamic over-current sensor and quick switch off

- Ground fault oberserver and quick switch off

- Monitoring of integrated sensors like temperature sensors…

- May also be combined with numerous other tests:

- Surge test

- Partial discharge test

- High voltage AC / DC

- Field rotation test

- Integration into test systems- the bonding process is performed as additional test step

- Integration in automatic production lines

Description

Excellent quality for your product.

SCHLEICH-bonding machines make it possible to bond and test self-bonding wired coils directly after the winding process. They allow the bonding and curing of coils for single- and three phase motors and all kinds of armatures and coils like speaker coils, magnet coils etc.

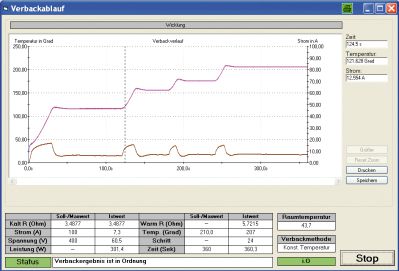

The bonding process is monitored by a PC and is performed by means of the controlled, electrical heating of the coils. Depending on the current density, different heating times result. Different current densities lead to bonding processes which may last from only a few seconds up to several minutes. After the heating phase it is also possible to constantly keep the reached temperature for a certain time. The result is a uniform temperature distribution within the winding and thus the best possible, homogeneous bonding in all parts of the winding.

Besides the use at single working stations our bonding machines are also perfectly suitable for the integration into fully-automatic production lines. Pallet control in a production line or the exchange of data with a PLC can also be easily realized. The machine´s design is intended to control up to eight independently running bonding processes and to display them on the screen.

Besides the use at single working stations our bonding machines are also perfectly suitable for the integration into fully-automatic production lines. Pallet control in a production line or the exchange of data with a PLC can also be easily realized. The machine´s design is intended to control up to eight independently running bonding processes and to display them on the screen.

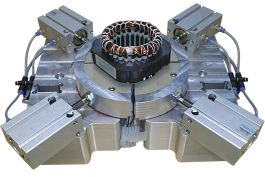

As system supplier we are able, in addition to the electric bonding machine itself, to also provide the entire mechanics which may consist of single bonding stations, a rotary indexing table or even an entire production line. Only the combination of these perfectly-matched components assures you the best possible production result.

Of course, also overhang forming tools and expanding mandrels belong to our range of products.

Furthermore our bonding machines may be extended by our MTC3- stator testers which make it possible to get detailed information about your product´s quality before and after the bonding process.

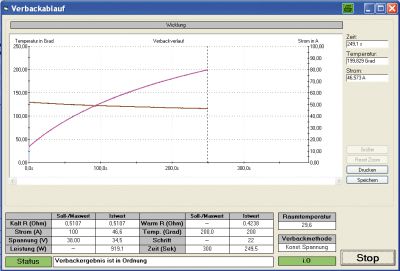

Bonding variant: Constant voltage method

A constant voltage is supplied to the winding. With increasing temperature also the winding´s resistance increases and thus the current decreases. Consequently, with rising temperature less power/energy is transferred into the winding.

The advantage of this method is, that the temperature rises rather slow which results in a good and even stator heating. Thus, the temperature deviation between overhang and slot is ideally low when reaching the bonding temperature.

However, as the densest current in the wire can only be reached at the beginning of the bonding process, no short bonding time is possible.

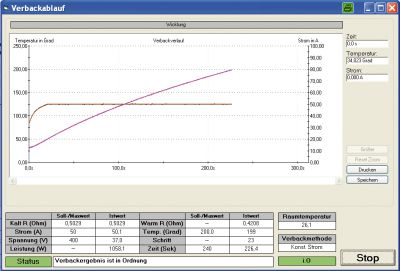

Bonding variant: Constant current method

This method keeps a constant current level during the bonding process. To be able to keep the decreasing current level constant while the resistance increases, the bonding machine automatically increases the voltage during the bonding process. That is why the final temperature is reached in shorter time compared to the bonding method with constant voltage. However, at this, the temperature may be unevenly distributed in the winding.

The advantage of this method is the achievement of short bonding times. However, in most cases an uneven temperature distribution occurs.

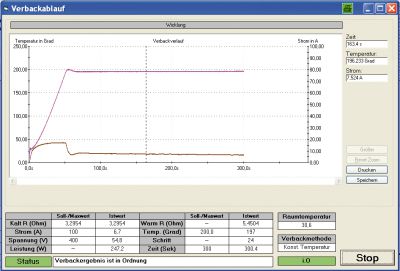

Bonding variant: Constant temperature method

During the constant-voltage or constant-current method the bonding process is stopped, as soon as the bonding temperature is reached.

The time, in which the self bonding coat melts at the wire´s surface and coalescenses with the neighbouring strands is relatively short at both methods. Due to this, it may happen, that the slot´s wires stay a bit cooler then the ones in the overhang, due to the surrounding laminated core. This could lead to a poorer quality.

With the constant-temperature method, as soon as the targeted temperature is reached, it is kept for a certain time. By this, the time in which the self bonding coat melts at the wire´s surface and coalescenses with the neighbouring strands, is extended.

Bonding method: Temperature profile method

Bonding with a temperature profile basically corresponds to bonding with constant temperature, but, however, at this method, several temperature levels are reached one after another.

At this, the temperature difference between hangover and slot may aready be adapted during lower pre-temperatures before the actual melting process.

This method is mainly used in cases, where the laminated core is rather long (compared to a relatively short hangover) and/ or if the laminated core´s dimensions are rather large.

Technology

Impressions

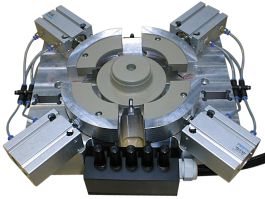

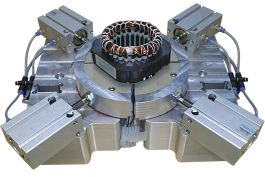

Bonding machine with production line

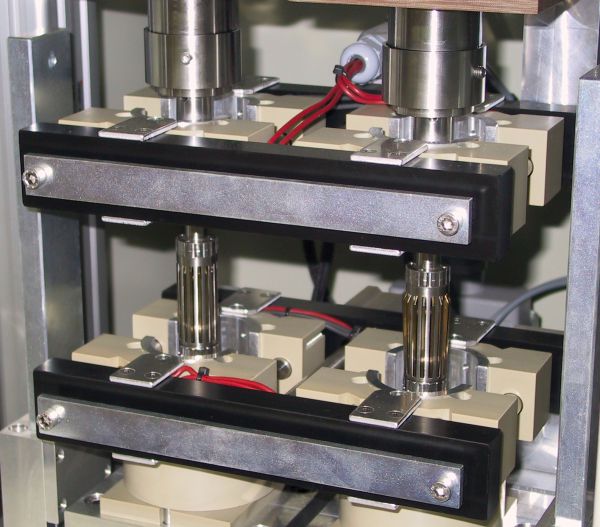

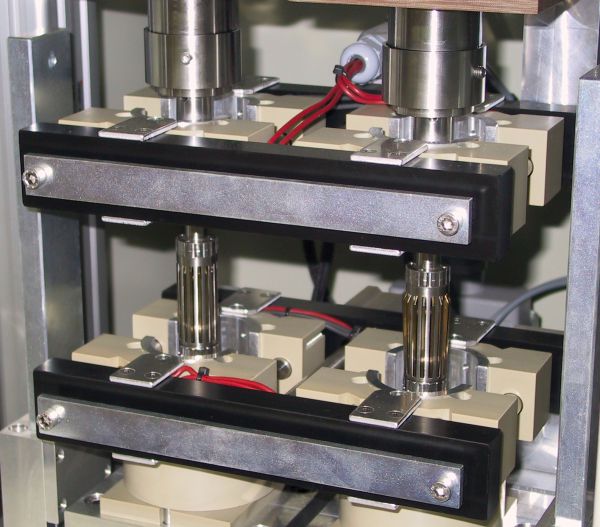

Dual station with expanding mandrel

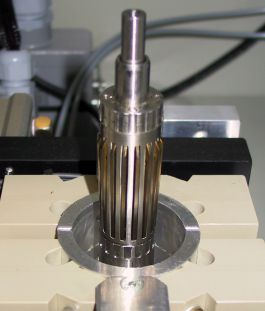

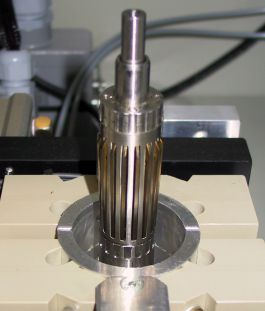

Contacting tool with expanding mandrel

Forming tool

Expanding mandrel with forming tool

Forming tools opened and closed

Form shaper for forming with pressing power

Applications

Impressions

Bonding machine with production line

Dual station with expanding mandrel

Contacting tool with expanding mandrel

Forming tool

Expanding mandrel with forming tool

Forming tools opened and closed

Form shaper for forming with pressing power

Accessories

Terminal blocks

Modular terminal blocks to contact loose lead ends- stackable 4-wire clamps

- modular design

- different designs and sizes

Kelvin Clamps

High-precision resistance measurement even for smallest resistances- condition for high-precise resistance measurements

- solid industrial quality

- 3 different sizes

Motor Terminal Plugs

Test plugs for contacting motor terminal boards- induction motor test plugs / motor terminal board plugs

- quick contact for 6, 8 or 9 bolts

- for different motor terminal board sizes

- for threaded bolts M4, M5, M6, M8 and M10

- without, with 1 or 2 motor grounding tips

- super simple test lead connection

- 4 patents pending

Special contactings

Customized solutions based on the modular SCHLEICH building kit- individual solutions

- for perfect 4-wire measurement

- float-mounted collets

analyzer

PC-Software for statistical analysis of test results- in-depth test result analysis

- production online monitoring

- informative statistics-report printout

Downloads

International PDFs

German PDFs

For further information please do not hesitate to contact our technical sales under:

- +49 2372 901 25 40

- Email request

print preview

Product comparison

| type of tester |

| delivery |

|

|

| Bonding Machines | Current-UV Impregnation Systems |

|

bandable enamelled wire electrically heated · ≤ 2.500 A · ≤ 1.000 V · online temperature monitoring · ≤ 250 A/mm² · voltage, current or temperature controlled · earth fault detector <10 μs off time · compatible with tests … |

heating with current · curing with UV light · ≤ 2500 A – ≤ 1.000 V · online temperature monitoring · ≤ 250 A/mm² · voltage, current or temperature controlled · can be combined with tests … |

| read more | read more |

| thermal-bonding machines | current-UV impregnation machines |

| order-related manufacturing | order-related manufacturing |

SCHLEICH is a leading manufacturer of electrical safety, functional, winding and electric motor testing technology.

SCHLEICH is a world-renowned company that focuses on the development of innovative products in the field of testing technology for electrical products of all kinds.

From A to Z - everywhere SCHLEICH testing technology is in use worldwide. Our customers come from over 50 countries and regions. Everything is developed and produced in Germany.

Quality work - Made in Germany.

2022 - SCHLEICH is awarded for the fifth time as TOP100-Innovator

2016 - SCHLEICH released the first VoltageAnalyzer for measuring the real voltage directly at the winding terminals

2012 - SCHLEICH is awarded as TOP100-Innovator for the first time

2005 - SCHLEICH released the first stator tester with partial discharge test

1995 - SCHLEICH integrates touch-displays into testing devices as a world leader

1990 - SCHLEICH released the first safety and function tester with fully automatic integrated test terminal changeover

1987 - SCHLEICH released the first surge tester with PC-control under DOS and fully automatic integrated test terminal changeover

1985 - SCHLEICH released the first MotorAnalyzer

1982 - SCHLEICH focuses fully on electrical test engineering of electrical products

1952 - SCHLEICH is founded as a motor repair shop

Pioneering spirit, competence, curiosity, brand new technologies and innovations. This is what the 145-strong SCHLEICH team stands for - led by Martin & Jan-Philipp Lahrmann. Father & son. Your guarantors for long-term partnership.