editor&printer

PC-Software for editing test sequences and for storing and printing test results.

With the editor&printer software from SCHLEICH, you can create and edit test plans for your GLP2-ce, -BASIC, -MODULAR or -BT directly on your PC. This way, you can continue testing efficiently and undisturbed, while the test plan editing is done on a Windows® computer.

Notice: The editor&printer software is included within the technology package for the GLP2!

Product consultant

Key-Facts

Centralized editing, storing and printing.

- WINDOWS® Software for editing test sequences

- Editing test sequences via PC instead in the GLP2-ce, -BASIC, -MODULAR, -BT

- Test sequence change management with necessary approval (dual control)

- For single and networked GLP2-testers

- Archiving of single test sequences

- Report printout of single test results

- Report printout of numerous test results

- Manual data transfer via USB-stick

- Automatic data transfer in computer network (LAN)

- integrated user management

- easy installation without special knowledge

Description

Typically test sequences are directly generated in the GLP2-ce, -BASIC, -MODULAR, or -BT test device. To do so, the touchdisplay or a keyboard, connected to the tester, is used.

With the editor&printer software, it is also possible to edit test sequences directly on a PC.

Generating test sequences on a PC brings the advantage, that it does not influence the operator during tests. The PC-software has the same user interface as the GLP2-ce, -BASIC, -MODULAR, or -BT. Thus, the operation is almost equal and therefore easy to understand and learn.

editor&printer is used under two different working conditions:

-

Data exchange via USB-flash drive| Offline-operation

-

Data exchange via network| Online-operation

Offline-operation| Data transfer via USB-flash drive

By means of the editor&printer software test sequences are maintained, edited and stored on your PC. As soon as the settings are finished, the software transfers the test sequences to an USB-flash drive. As next step, the USB-drive has to be connected to the tester. The tester downloads all test sequences and automatically stores them in the internal database. Afterwards the test sequences are available like usual.

In case several identic testers are in use, one ofter another should be updated with the new test sequences to avoid having different test sequences on different testers for the same test task!

We recommend to consistently edit the test sequences on the PC and to directly transfer the updated ones to the tester.

Alternatively test sequences may still be edited in the tester. But to avoid differences to the ones in the software, the adjusted test sequences should be immediately transferred to the PC via USB-flash drive. By this, different data inventory is avoided.

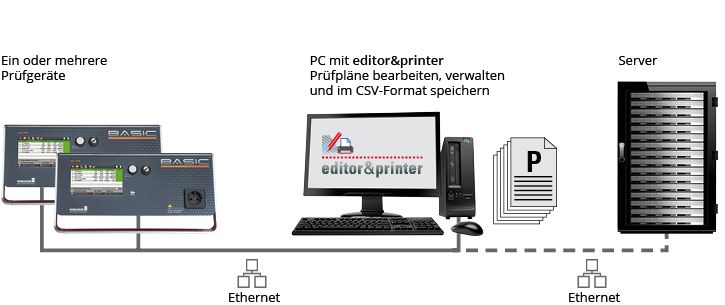

Online-operation | Data exchange via network

Under perfect conditions the tester/s are part of a computer network. But a network makes only sense, if the data is stored centrally. A central storage location for all test sequences is to be defined, which can be any PC in the network. Installing a special software on the PC is not necessary.

Also the PC with the editor&printer installation is in this network. With editor&printer you manage, edit and store test sequences. The data is stored in the central storage location in the network.

In case a tester requests a test sequence, it is loaded from the central storage location in the network. This is perfect, as all testers of the same type always use the same test sequences.

Thus, the network operation gives you the perfect condition for an ISO 9001-compliant production.

Of course, the test sequence may also be edited directly in the tester, which automatically stores the changes in the central storage location afterwards. After this, the other testers and the editor&printer software have automatic access to the revised test sequence.

Printout

editor&printer is also equipped with a useful printing function.

As the testers are not only able to store test sequences but also test results on a central PC, with editor&printer you may easily search within the test results and print them in a clearly arranged report.

You can search for single tests or even entire orders. The up to 10 freely-configurable order inputs (e.g. serial nimber, typem charge, commission and more) are entered in the tester. The tester transfers the inputs with the test results to the PC and stores them there.

With editor&printer you search the corresponding test results to your search criteria. Editor&printer presents them clearly-arranged in a table.

You can see the results in total or in detail, test step per test step.

Furthermore you can either print single or all test results.

Technology

Printout:

- in a predefined PDF template

- with your company logo

- with your company contact data

Storing:

- MS-SQL-Server-Express® or MS-SQL-Server® Data base

- unlimited quantity of test results

Languages:

- GER

- EN

- ESP

- FR

- IT

- PL

Operating System:

- WINDOWS 10®

Downloads

International PDFs

German PDFs

For further information please do not hesitate to contact our technical sales under:

- +49 2372 901 25 40

- Email request

print preview

Product comparison

SCHLEICH is a leading manufacturer of electrical safety, functional, winding and electric motor testing technology.

SCHLEICH is a world-renowned company that focuses on the development of innovative products in the field of testing technology for electrical products of all kinds.

From A to Z - everywhere SCHLEICH testing technology is in use worldwide. Our customers come from over 50 countries and regions. Everything is developed and produced in Germany.

Quality work - Made in Germany.

2022 - SCHLEICH is awarded for the fifth time as TOP100-Innovator

2016 - SCHLEICH released the first VoltageAnalyzer for measuring the real voltage directly at the winding terminals

2012 - SCHLEICH is awarded as TOP100-Innovator for the first time

2005 - SCHLEICH released the first stator tester with partial discharge test

1995 - SCHLEICH integrates touch-displays into testing devices as a world leader

1990 - SCHLEICH released the first safety and function tester with fully automatic integrated test terminal changeover

1987 - SCHLEICH released the first surge tester with PC-control under DOS and fully automatic integrated test terminal changeover

1985 - SCHLEICH released the first MotorAnalyzer

1982 - SCHLEICH focuses fully on electrical test engineering of electrical products

1952 - SCHLEICH is founded as a motor repair shop

Pioneering spirit, competence, curiosity, brand new technologies and innovations. This is what the 145-strong SCHLEICH team stands for - led by Martin & Jan-Philipp Lahrmann. Father & son. Your guarantors for long-term partnership.