Custom-made test covers

Test covers – individually designed and crafted to meet your specifications

Test covers serve to protect the operator and prevent contact with the test object during the test. We supply an extensive range of standard test cages. Special variants in various designs are also available or are specially designed for your application and manufactured by us. In addition to the test covers, we also supply the suitable contacting of the test specimen.

Product consultant

Key-Facts

Perfect protection against accidental contact – custom-made.

-

Mechanically solid and durable constructions

- Developed for rough industrial applications

- Automatic start when cover is closed

-

Immediate interruption when opening the cover during tests

-

Up to Performance Level PLe

- Customized solutions to integrate your test object (DUT)

- Customized solutions with integrated conveyor

- Customized solutions for the installation of manual contactings

- Customized solutions for the installation of full automatic contactings

- Customized solutions for automatic production lines

Description

Customized solutions- perfectly matched to your application.

Test covers serve to protect the operator and prevent contact with the test object during the test.

Test covers from SCHLEICH put the safety of the user in the foreground: In accordance with valid standards, we protect users by means of mandatory protection against accidental contact.

Applications

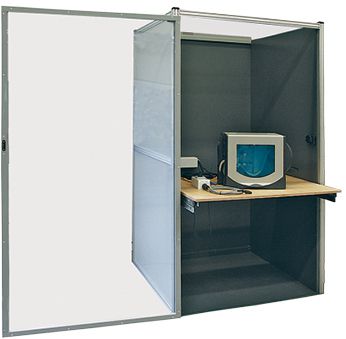

Special test cover with acoustic insulation

- Soundproofed to protect operator and environment from noise emissions

- A variety of quick-change test adaptor plates for fast insertion and removal of different types of DUTs

- Optical evaluation electronics for sense of rotation and RPM measurement + vibration measurement integrated in the adaptor plate

Test cover with integrated assembly line for assembly pallets

- Automatic side doors

- Front with light grid

- Contactings from above

- Integration in assembly line

Large test cover with integrated assembly line

- Side doors with pneumatic cylinders

- Front with light grid

- contactings from above

Large special cover with door

- accessible with pallet trolley

- transparent door

- all metal parts of the outer construction in the test room are covered for insulation material against voltage

Customized test cover with Faraday cage

- The test cover is driven upwards via a sloping ramp. Thus, the test area is completely accessible in opened condition.

- To avoid interfering electromagnetic fields during measurement, the test cover is equipped with an Faraday cage.

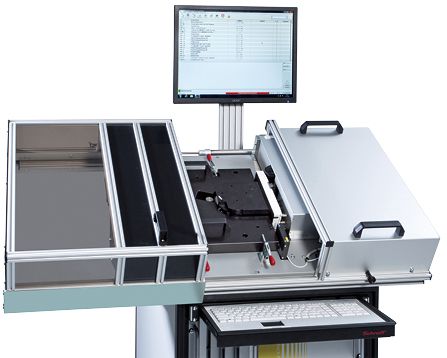

Customized test cover on a test bench.

- The test cover is intended to protect against accidental contact.

- It is used for light shading, since a camera is integrated in the test setup for tresting an LCD display from the DUT.

Downloads

International PDFs

German PDFs

For further information please do not hesitate to contact our technical sales under:

- +49 2372 901 25 40

- Email request

print preview

Product comparison

| test cover type |

| model range |

| width x depth x height (inside) |

| width x depth x height (outside dimensions) |

| height of floor box |

| performance level (PL) |

| rated voltage |

| LED result lights |

| warning lights |

| limit switch |

| opening angle of the test cover |

| automatic opening |

| automatic guard closing |

| guard locking during the test |

| industrial socket for test cable |

| carrying capacity of the base |

| ESD design |

| Faraday cage design |

| pass through of conveyor system |

| bottom with ball transfer system |

| table frame |

| installed on rolling container |

| Installation in SCHLEICH rolling tables |

| CAD data available |

| delivery |

|

|

|

|

|

|

| Single Test Covers | Dual Test Covers | Safety-Light Curtains | Test Cabins | Test facilities | Custom-made test covers |

|

various sizes ⋅ ergonomic ⋅ smooth-running ⋅ long service life ⋅ up to Performance Level PLe ⋅ integrated result lights ⋅ automatic opening ⋅ guard locking ⋅ adapter installation … |

alternating testing ⋅ various sizes ⋅ ergonomic ⋅ smooth-running ⋅ long service life ⋅ up to Performance Level PLe ⋅ integrated result lights ⋅ with guard locking ⋅ plenty of space for adapter installation … |

various sizes ⋅ 1-, 2-, 3- or 4-sided open and monitored ⋅ for large or bulky test objects ⋅ accessible with pallet jack ⋅ marking of the approved test area … |

safety door or roller shutter ⋅ up to Performance Level PLe ⋅ ideal for large devices under test ⋅ suitable for pallet trolleys ⋅ sturdy industrial quality ⋅ long service life … |

accessible by forklift ⋅ several access doors ⋅ monitoring with safety PLC ⋅ up to performance level PLe ⋅ several emergency stop buttons and warning lights ⋅ robust industrial quality ⋅ long service life … |

Individual customer-specific solutions of any kind, application and size |

| read more | read more | read more | read more | read more | read more |

| single test cover | double test cover | safety light curtain | test cabin | test facility | — |

|

model 13-R2 model 10 model 21 model 20 model 1 model 0 |

model 3 model 12 |

— | — | — | — |

|

458 x 600 x 400 mm 800 x 600 x 500 mm 1100 x 600 x 500 mm 1000 x 600 x 500 mm 900 x 600 x 500 mm 800 x 754 x 500 mm 900 x 800 x 645 mm 900 x 730 x 330 mm 700 x 730 x 330 mm 500 x 730 x 330 mm 230 x 350 x 195 mm |

688 x 536 x 345 mm 588 x 536 x 345 mm 488 x 536 x 345 mm 385 x 536 x 345 mm |

— | — | — | — |

|

620 x 782 x 515 mm 946 x 837 x 625 mm 1246 x 837 x 625 mm 1146 x 837 x 625 mm 1046 x 837 x 625 mm 946 x 987 x 625 mm 1046 x 987 x 770 mm 946 x 792 x 520 mm 746 x 792 x 520 mm 546 x 792 x 520 mm 265 x 390 x 305 mm |

1400 x 617 x 500 mm 1200 x 617 x 500 mm 1000 x 617 x 500 mm 800 x 617 x 500 mm |

— | — | — | — |

| — | 75 mm | — | — | — | — |

| reachable up to PLe; dual-channel monitoring | reachable up to PLe; dual-channel monitoring | reachable up to PLe; dual-channel monitoring | reachable up to PLe; dual-channel monitoring | reachable up to PLe; dual-channel monitoring | reachable up to PLe; dual-channel monitoring |

|

max. 12 kV AC / 16 kV DC max. 6 kV AC / 8 kV DC max. 8 kV AC / 10 kV DC max. 3 kV AC/DC |

max. 6 kV AC / 8 kV DC max. 8 kV AC / 10 kV DC |

— |

various models up to max. 50 kV AC/DC max. 6 kV AC / 8 kV DC |

— | max. 100 kV |

|

GO / NO GO - integrated in the test area GO / NO GO - mounted on the test cover |

GO / NO GO - integrated in the test area | — |

GO / NO GO - at the front GO / NO GO - integrated in the test area |

— | GO / NO GO - integrated in the test area |

| — | optional 2 pieces | — | — | — | — |

| — | 2 x CAT IV limit switches, contactless | — | — | — | — |

| almost 90° mechanical | almost 90° mechanical | — | — | — | — |

|

not possible optional yes |

not possible optional |

— |

not possible optional |

— | optional |

|

not possible yes |

not possible | — |

optional not possible |

— | optional |

|

optional, pneumatic or electric yes optional, pneumatic |

yes not possible |

— | optional, pneumatic or electric | — | optional, pneumatic or electric |

|

prepared for 3 pieces prepared for 4 pieces prepared for 1 piece |

prepared for 2 pieces | — | — | — | — |

|

15 kg / 33 lbs 150 kg / 330 lbs 25 kg; 50 kg optional / 55 lbs; 110 lbs optional 50 kg / 110 lbs |

50 kg; 150 kg optional / 110 lbs; 330 lbs optional 20 kg; 50 kg optional / 44 lbs; 110 lbs optional 15 kg; 50 kg optional / 33 lbs; 110 lbs optional |

— |

15 kg; 150 kg optional / 33 lbs; 330 lbs optional 2000 kg / 4400 lbs |

— | — |

| optional | optional | — | — | — | optional |

| optional |

optional not possible |

— | — | — | — |

| optional, max. 400 mm wide | optional, max. 400 mm wide | optional, max. 400 mm wide | optional, max. 400 mm wide | — | optional, max. 400 mm wide |

| optional | optional | optional | optional | — | optional |

|

no optionally with adjustable feet optionally with castors with adjustable feet included in delivery |

optionally with adjustable feet optionally with castors |

— |

with adjustable feet included in delivery optionally with castors |

— | — |

|

not possible optional |

not possible optional |

— | not possible | — | — |

|

optional possible not possible |

— | — | — | — | — |

| yes, on request | yes, on request | yes, on request | yes, on request | — | — |

|

on stock order-related manufacturing |

order-related manufacturing | order-related manufacturing | order-related manufacturing | — | order-related manufacturing |

SCHLEICH is a leading manufacturer of electrical safety, functional, winding and electric motor testing technology.

SCHLEICH is a world-renowned company that focuses on the development of innovative products in the field of testing technology for electrical products of all kinds.

From A to Z - everywhere SCHLEICH testing technology is in use worldwide. Our customers come from over 50 countries and regions. Everything is developed and produced in Germany.

Quality work - Made in Germany.

2022 - SCHLEICH is awarded for the fifth time as TOP100-Innovator

2016 - SCHLEICH released the first VoltageAnalyzer for measuring the real voltage directly at the winding terminals

2012 - SCHLEICH is awarded as TOP100-Innovator for the first time

2005 - SCHLEICH released the first stator tester with partial discharge test

1995 - SCHLEICH integrates touch-displays into testing devices as a world leader

1990 - SCHLEICH released the first safety and function tester with fully automatic integrated test terminal changeover

1987 - SCHLEICH released the first surge tester with PC-control under DOS and fully automatic integrated test terminal changeover

1985 - SCHLEICH released the first MotorAnalyzer

1982 - SCHLEICH focuses fully on electrical test engineering of electrical products

1952 - SCHLEICH is founded as a motor repair shop

Pioneering spirit, competence, curiosity, brand new technologies and innovations. This is what the 145-strong SCHLEICH team stands for - led by Martin & Jan-Philipp Lahrmann. Father & son. Your guarantors for long-term partnership.