GLP3

Unlimited class leading test technology.

The TOP Class of test and measurement technology.

The multitester par excellence.

Your plus in versatility, profitability and speed.

Flexible ⋅ intuitive ⋅ uncomplicated ⋅ feasible.

Product consultant

Key-Facts

Unlimited test technology in perfection.

- PE/ ground test up to 200 A

- Insulation test up to 10 kV

- High voltage test AC up to 100 kV

- High voltage test DC up to 100 kV

- Leakage current test 30 mA – 1 MHz

- Functional test 1- and 3-phase up to 1,000 A

- Perfect for complex test benches or interlinked assembly- and test lines

- All kinds of safety tests

- Measurement of physical units: Pressure, temperature, leakage …

- Visual inspection systems

- Up to 500 programmable test connections

- Multi stations with up to 50 test stations

- Fast, precise measurements with latest DSP-technology (digital signal processor)

- High-resolution measurement technology for all test methods

- Large switch matrix modules for all kind test methods

- PLe, SIL3, Kat4 Safety circuit

- High process reliability

- Freely-programmable in- and outputs

- Integrated industrial PC with Windows 7® or Windows 10®

- Central database for millions of test sequences and test results – SQL-server

- Extensive statistical analyses – Trending, Gaussian distribution, FPY …

- Traceability for all test object´s components

- User administration

- Configurable test report printout

- Freely configurable label print for thermal transfer printers

- Several label printers addressable

- Reading of any 1D- and 2D-barcodes

- Remote control: RS232, SPS, PROFIBUS, PROFINET, CAN, DeviceNet, Ethernet, EtherCat, USB …

- Communication with the tester: RS232, PROFIBUS, PROFINET, CAN, Ethernet, EtherCat, USB, analog, PWM …

- Full network connectivity

- Data exchange with ERP- and CAQ-systems

- Connection to MES-systems

- Ideal OEM-conditions for easy integration in automatic lines

- Remote maintentance and remote calibration possible

Description

Test technology 4.0

The GLP3-Windows® testers are our premium testers to test a variety of different complex products. They are preferably used to test electric component groups, run-in test benches, power supplies, cables, washing machines and more and are ideally suited for complex test benches and interlinked assembly- and test lines.

After connecting all test object´s connections, the different types of tests and connections are automatically switched over by the tester´s internally installed switchover. Each test step is automatically evaluated and the operator gets a clearly reproducible Go/ No Go result at the end of the entire test sequence.

SCHLEICH was one of the first tester manufacturers which consistently and successfully integrated PCs in the GLP3 testers to facilitate measuring, controlling and storing processes. Based on years of experience with the system, our engineers and technicians were able to develop a matured test system with comprehensive software. Many useful software tools are included in our standard scope of delivery.

Hard- and Software are developed and manufactured in-house at SCHLEICH. To keep our pole position in the test equipment market, also established products are further enhanced. The software and the database are at the most modern state of the proven Microsoft® technology. Our versatile innovations always set new technological standards for modern test benches with Windows®. The system offers a clear display of the test process for the operator and extensive input- and configuration features for the setter.

Also SCHLEICH´s quality management is striking. For this purpose, an extensive statistical analysis in integrated in the tester, which leaves no questions unanswered and which allows you to document your proven quality to yor customer by means of a variety of different test report printouts.

Customize your tester!

The SCHLEICH MODULAR CONCEPT makes it possible.

Based on this concept, the GLP3 testers offer almost unlimited possibilities to combine and to integrate different safety- and functional test methods in only one device.

You can select from a wide range of test methods the ones you need.

If only one or a variety of test methods, you define the configuration! This means, that your GLP3 e.g. may be configured as high-voltage-, or PE/ ground bond resistance tester. For more complex test tasks, a combination of all test methods might be needed.

The SCHLEICH·MODULAR·CONCEPT of the GLP3 class allows you to configure a tester, perfectly matching to your requirements. A further advantage is, that the versatility is realized by installing all tests in a compact, modular housing and not by integrating several single testers in an oversized test cabinet. The housing´s size results from type and extent of the different tests.

This flexibility not only offers you a huge price benefit, furthermore each tester contains our engineer´s experience from over 14.000 installations. This experience flows consistently and without any compromise in further developments.

This is “customer based technology”.

If manual or automatic single-, double or multi test stations, if with or without test cover or table or testing in automatic assembly lines. There are no limits regarding the variety of GLP3 applications.

Technology

Automation and Interfaces.

- digital I/O, (input/output 24 V to PLC)

- RS232 via SCHLEICH communication protocol

- LAN via SCHLEICH communication protocol

- LAN via TCP/IP

- USB

- PROFIBUS

- PROFINET

- EtherCAT

- CANopen

- CAN-Automotive

- DeviceNet and more …

- individual special solution …

Benefits at a glance.

Measurement technology

- Precise and fast measurements

- TRMS – true R.M.S. measurement

- R.M.S.- and peak value measurement

- Effective and apparent current measurement, cosφ

- Effective and apparent power measurement

PE/ Ground AC

- PE/Ground resistance AC

- 10 – 200 A AC, adjustable, electronically controlled

- Current steps 1 A

- 6, 12, 18, 24 V AC

PE/ Ground DC

- PE/Ground resistance DC

- 1 – 200 A DC, adjustable, electronically controlled

Insulation resistance DC

- Insulation resistance

- 30 – 10.000 V DC, adjustable, electronically controlled

- 100 kΩ – 10 GΩ

- „Warm insulation resistance test”

High-voltage AC

- 50 – 10.0000 V AC, adjustable

- with safety current limiting max. 3 mA

- without safety current limiting max. 2 A

- ARC-Detection

- „Warm high-voltage test”

High-voltage DC

- 50 – 50.000 V DC, adjustable, electronically controlled

- with safety current limiting max. 4 mA

- without safety current limiting max. 100 mA

- „Warm high-voltage test”

Function AC

- 1- and 3-phase

- from1 – 1.000 V AC

- max. 500 A

- apparent-, active and reactive/ idle power

- cos φ

- incl. short-circuit test

Function DC

- 1 – 500 V DC

- max. 500 A

- incl. short-circuit test

Leakage current

- according to standard EN60990 & EN60601 & various UL-Standards

- 0,1 μA – 30 mA

- R.M.S., peak value, DC-/AC share

- Frequency range up to 1 MHz

- medical

- Patient leakage current measurement

- Patient auxiliary leakage current

- Touch current measurement– between 2 test probes

- Patient interfaces 8 – extendable on request

- Operational ground of the test object

- two test probe connections

- insulated contactings S2 & S3

- on request, all connections with high-voltage test available

Equivalent leakage current

- according to standard with convertion to any rated voltage

Residual voltage

- 1- and 3-phase

Resistance

- 1 μΩ – 500 MΩ

- test current 1 – 200 A

- 4-wire technolgy

Inductance

- inductance measurement via integrated measuring bridge

- 4-wire technology

Impedance

- impedance measurement via integrated measuring bridge

- 4-wire technology

Capacity

- capacity measurement via integrated measuring bridge

- 4-wire technology

Internal resistance

- battery´s inner resistance

- 1 μΩ – 10 Ω4

- 4-wire technology

Free analog inputs

- Measuring ranges 50 mV, 500 mV, 5 V, 50 V, 500 V

- AC or DC

- multi-channel

- insulated

⇒ Find more details under Downloads.

Applications

Customized solutions.

Luminaire inspection

- Semi-automatic luminaire test bench

- With 15 lamp adapters

- Pick-By-Light operator´s guidance

- Label print by 2 different printers

Inspection of heatings with rotary indexing table

- Automatic test run

- Linear conveyor with handling

- Automatic contacting

- All-in-one solution incl. entire mechanics from SCHLEICH

Run-in test bench for electronic assembly

- 6 test stations

- Integrated vibraction unit

- Integrated temperature control of assemblies

- Extended variants with 50 test stations

Tester for frequency converters

- Fully-automatic load test

- Automatic calibration of the test object

Tester for transformers

- Power measurement for up to 6 transformers at the same time

- Heating measurement of windings and temperature-rise determination

Tester for component groups

- Several test stations

- Automatic CPU-flashing

- Automatic calibration

- Integrated needle adapter

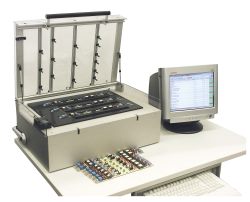

Komplex Matrix (interior view of the tester)

- Tester with over 500 clamps

- High-voltage switchover up to 6.000 V, 1 A

Accessories

Barcode Scanner

Scanning of serial numbers, product types, production specifications, ...- various 1D & 2D-barcode scanners

- reading of order data, operator names, serial numbers and more

Label Printers

Label printing of type plates, device and test result decals, ...- various thermal transfer printers

- printout with order data, serial number, and more

Single Test Covers

Testing with protection against accidential contact- various sizes

- ergonomic – smooth-running – versatile

- sturdy industrial quality – long service life

- up to Performance Level PLe

- built-in result lights

- plenty of space for adapter installations

- optional: automatic opening – guard locking …

Test Cabins

Testing with protection against accidential contact- with safety door or roller shutter

- for large or bulky test objects

- suitable for pallet trolleys

- various sizes

- robust industrial quality – long service life

- up to Performance Level PLe

- integrated door locking

- custom solutions …

Safety-Light Curtains

Testing without protection against accidental contact- 1-, 2-, 3- or 4-sided open and monitored

- two-channel monitoring of safety

- for large or bulky test objects

- accessible by pallet jack

- marking of the approved test area

- installation of contacts and clamps

- various sizes

- custom solutions …

Custom-made test covers

Test covers – individually designed and crafted to meet your specifications- individual customer-specific solutions of any kind, application and size

Test facilities

Testing with protection against accidential touch- individual special solutions

- multiple access doors

- for large or bulky test objects

- passable with fork lift truck

- robust industrial quality – long service life

- up to Performance Level PLe – evaluation with safety PLC

- several emergency stop buttons and warning lights

- integrated door locking …

analyzer

PC-Software for statistical analysis of test results- in-depth test result analysis

- production online monitoring

- informative statistics-report printout

Connection boxes

Connection panel for connecting your device under test- 1, 2, 3 or 4 test sockets for different country standards

- quick pressure clamps for single leads

- 4 mm laboratory sockets

- high current socket for protective conductor test probe

- for single-phase and three-phase test objects

- customized solutions

Test dummy, self-test black box

Dummy test used for standardized functionality control- for daily inspection

- universal blackboxes

- factory calibration, also according to DAkkS

Kelvin Clamps

High-precision resistance measurement even for smallest resistances- condition for high-precise resistance measurements

- solid industrial quality

- 3 different sizes

Terminal blocks

Modular terminal blocks to contact loose lead ends- stackable 4-wire clamps

- modular design

- different designs and sizes

Pneumatic clamps

Automatic pneumatic quick clamping- automatic clamp with pneumatic cylinder

- push-button for fast release

- for different wire diameters

- hole diameter with 4, 6 or 9 mm

Special contactings

Customized solutions based on the modular SCHLEICH building kit- individual solutions

- for perfect 4-wire measurement

- float-mounted collets

Test Probes

For manual PE, insulation resistance and leakage current tests- built-in start button

- built-in 3-color LED

Warning lights

Warning and indication of hazardous test voltage- warning of hazardous test voltage

- only required for touchable test objects

- not necessary when test cover is used

High-voltage test pistols

Safe testing with high voltage- for 6, 10 or 12 KV AC/DC

- without or with integrated start button

- optional with 4-wire technology (4W)

Two-Hand Operation

Protection against electrical hazards- dual-circuit safety with BG-approval

- solid and stable

- 2 different models

Test Tables

Individually designed and custom-made.- professional test tables:

- according to BG-guidelines

- customized for your test task

Test tables with rollers

Mobile test equipment use in your shop floor- mobility at testing

- perfect for workshop applications

- ergonomic design with storage space

High-Voltage Relays

Switching and disconnecting high voltages safely- high-voltage relays

- switch matrixes

- safe isolation

- with single or double changeover contacts

- SPDT “Single Pole Double Throw”

- for rail mounting DIN50022

- system components for DIY

High-Voltage Cables

Safe conducting and distribution- for a variety of applications

- cables up to 100 kV

High-Voltage Connectors

Connect high-voltage- up to 100 kV

- pluggable

- screw fitting

- made of plastic

- made of metal

Calibration Resistors

High precision for verifying measurement accuracy- precision resistors for the annual calibration

- low drift

- factory calibration

- DAkkS calibration (optional)

Downloads

International PDFs

German PDFs

- Schleich Modular Concept

- Gehäusevarianten GLP3

- Software GLP3

- Prüfmethodenumschaltung GLP3

- Kabelbaumprüfung GLP3

- Lampenersatzlast GLP3

- Projektbeispiele GLP3

- Broschüre Prüfhauben | Prüfkabinen | Schutzvorrichtungen

- Sicherheits- und Funktionsprüfgeräte » Der Gerätevergleich

- Sicherheits- und Funktionsprüfgeräte » Die Produktübersicht

- SCHLEICH » Die Unternehmensbroschüre

For further information please do not hesitate to contact our technical sales under:

- +49 2372 901 25 40

- Email request

print preview

Product comparison

| type of tester |

| PE/GB |

| insulation |

| high voltage AC |

| high voltage DC |

| function AC 1-phase |

| function AC 3-phase |

| leakage current |

| luminaire test |

| key switch |

| safety concept |

| two-hand start |

| test terminals |

| test connections |

| connection box |

| test cover |

| automation |

| database |

| test plans |

| test results |

| communication |

| test report print-out |

| label print-out |

| scanner port |

| password protection |

| user management |

| SmartCalibration Ready |

| operating system |

| Operating System Technology Package |

| display |

| display Technology Package |

| delivery |

|

|

|

|

|

|

| HandHeld | GLP1-g | GLP2-BASIC | GLP2-MODULAR | GLP2-Technology Package | GLP3 |

|

portable – lightweight – PE test up to 10 A AC – insulation test up to 1,000 V – carrying strap – transport case – outdoor – PC software … |

compact standard tester – up to 9 test methods in one device – table-top unit or 19″ rack – VDE/EN/UL – manual & automated testing – production – automation – laboratory – QA – service – PC software … |

compact standard tester – up to 21 test methods in one unit – table-top unit or 19″ rack – VDE/EN/UL … – manual & automated testing – production – automation – laboratory – QA – network – protocol & label printing – Windows® … |

modular – customer-specific – VDE/EN/UL… – manual & automatic – production – automation – laboratory – QA – network – protocol & label printing – Windows®… |

upgrade your GLP2-BASIC/MODULAR – external PC – Windows 10® – more convenience and intuitive operation – optimized visualization – even faster inputs … |

TOP-Class · modular · customized · no limits · VDE/EN/UL/IEC … · production · automation · worldwide networking · databases · statistics · data import/export · Windows10® · complex systems … |

| read more | read more | read more | read more | read more | read more |

|

PE/GB-resistance testers insulation testers (IR) safety testers ALL-IN-1 |

PE/GB-resistance testers insulation testers (IR) high-voltage testers safety testers ALL-IN-1 safety & function testers ALL-IN-1 |

high-voltage testers safety testers ALL-IN-1 safety & function testers ALL-IN-1 |

PE/GB-resistance testers insulation testers (IR) leakage-current testers high-voltage testers safety testers ALL-IN-1 safety & function testers ALL-IN-1 |

— |

safety testers ALL-IN-1 safety & function testers ALL-IN-1 |

| 1–10 A˜ 6/12 Veff |

1–10 A˜ 6/12 Veff 1–30 A˜ 6/12 Veff 1–50 A˜ 6/12 Veff 1–40 A˭ 12 V 1–75 A˜ 6/12 Veff |

1–30 A˜ 6/12 Veff |

1–10 A˜ 6/12 Veff 1–30 A˜ 6/12 Veff 1–200 A˜ ˭ up to 50 V custom |

— |

1–10 A˜ 6/12 Veff 1–30 A˜ 6/12 Veff 1–200 A˜ ˭ up to 50 V custom |

| 0–1 kV ˭ max. 30 MΩ | 0–1 kV ˭ max. 10 GΩ | 0–1 kV ˭ max. 10 GΩ |

0–1 kV ˭ max. 10 GΩ up to 50 kV˭ up to 10 TΩ custom |

— |

0–1 kV ˭ max. 10 GΩ up to 50 kV˭ up to 10 TΩ custom |

| — |

0–6 kV˜ max.3 mA safety 0–6 kV˜ max. 100 mA 0–6 kV˜ max. 200 mA 0–12 kV˜ max. 100 mA 0–15 kV˜ max. 50 mA 0–30 kV˜ max. 30 mA 0–50 kV˜ max. 25 mA |

0–6 kV˜ max.3 mA safety 0–6 kV˜ max. 100 mA |

0–6 kV˜ max.3 mA safety 0–6 kV˜ max. 100 mA custom |

— |

0–6 kV˜ max.3 mA safety 0–6 kV˜ max. 20 mA 0–6 kV˜ max. 100 mA 0–6 kV˜ max. 200 mA 0–12 kV˜ max. 100 mA custom |

| — |

0–4 kV ˭ max. 10 mA 0–6 kV ˭ max. 10 mA 0–6 kV ˭ max. 20 mA 0–10 kV ˭ max. 6 mA |

0–6 kV ˭ max. 4 mA 0–6 kV ˭ max. 100 mA |

0–6 kV ˭ max. 4 mA 0–6 kV ˭ max. 100 mA custom |

— |

0–4 kV ˭ max. 10 mA 0–6 kV ˭ max. 10 mA 0–6 kV ˭ max. 20 mA 0–10 kV ˭ max. 6 mA custom |

| — | 0–250 V˜ max. 5 A |

0–250 V˜ max. 5 A 230 V˜ max. 16 A |

according to your requirements | — | according to your requirements |

| — | — | — | according to your requirements | — | according to your requirements |

| — | — |

electronic products EN60990 medical products EN60601 UL compliant 1-phase |

electronic products EN60990 medical products EN60601 UL compliant 1-phase 3-phase up to 1 MHz customized |

— |

electronic products EN60990 medical products EN60601 UL compliant 1-phase 3-phase up to 1 MHz customized |

| safety | safety and function |

safety and function dimming: analogue, digital, ECG communication, DALI... parameterize, configure LED test with plug&play comBOX |

safety and function dimming: analogue, digital, ECG communication, DALI... parameterize, configure LED test with plug&play comBOX |

— |

safety and function dimming: analogue, digital, ECG communication, DALI... parameterize, configure |

| — | for HV-release | for HV-release | for HV-release | — | — |

| — | two-channel | two-channel | two-channel | — | two-channel |

| — | possible | possible | possible | — | possible |

| L1, N, PE | L1, N, PE | L1, N, PE |

L1, N, PE L1, L2, L3, N, PE made to your specifications |

— |

L1, N, PE L1, L2, L3, N, PE made to your specifications |

|

test socket, country-specific test probe |

test socket, country-specific test probe test pistols test socket at the rear, 10-pole, optional |

test socket, country-specific test probe test pistols test socket at the rear, 10-pole, optional |

according to your requirements | — | according to your requirements |

| — | possible | possible | possible | — | possible |

| — | possible | possible | possible | — | possible |

| — |

with digital I/O with RS232 via SCHLEICH communication protocol with USB via SCHLEICH communication protocol with LAN via SCHLEICH communication protocol |

with digital I/O with RS232 via SCHLEICH communication protocol with LAN via SCHLEICH communication protocol with LAN via SCPI commands with LAN via TCP/IP Socket Communication with PROFIBUS with PROFINET with EtherCAT with CANopen made to your specifications |

with digital I/O with RS232 via SCHLEICH communication protocol with LAN via SCHLEICH communication protocol with LAN via SCPI commands with LAN via TCP/IP Socket Communication with PROFIBUS with PROFINET with EtherCAT with CANopen made to your specifications |

with digital I/O with RS232 via SCHLEICH communication protocol with LAN via SCHLEICH communication protocol with LAN via SCPI commands with LAN via TCP/IP Socket Communication with PROFIBUS with PROFINET with EtherCAT with CANopen made to your specifications |

with digital I/O with RS232 via SCHLEICH communication protocol with LAN via SCHLEICH communication protocol with LAN via TCP/IP Socket Communication with PROFIBUS with PROFINET with EtherCAT with CANopen with CAN Automotive with DeviceNet made to your specifications |

| — | — |

file system SQL |

file system SQL |

file system SQL |

ACCESS SQL ORACLE |

|

import from PC, PLC, MES, ... import from LabVIEW® |

stored in the tester import from PC, PLC, MES, ... import from LabVIEW® |

stored in the tester stored in the tester and network import from PC, PLC, MES, ... import from LabVIEW® import from ERP system, e.g. SAP® |

stored in the tester stored in the tester and network import from PC, PLC, MES, ... import from LabVIEW® import from ERP system, e.g. SAP® |

stored in the tester stored in the tester and network import from PC, PLC, MES, ... import from LabVIEW® import from ERP system, e.g. SAP® |

stored in the tester stored in the tester and network import from PC, PLC, MES, ... import from ERP system, e.g. SAP® |

|

cached in the tester transfer to PC, PLC, MES, ... transfer to LabVIEW® |

cached in the tester transfer to PC, PLC, MES, ... transfer to LabVIEW® |

cached in the tester or network transfer to PC, PLC, MES, ... transfer to LabVIEW® transfer to ERP system, e.g. SAP® |

cached in the tester or network transfer to PC, PLC, MES, ... transfer to LabVIEW® transfer to ERP system, e.g. SAP® |

cached in the tester or network transfer to PC, PLC, MES, ... transfer to LabVIEW® transfer to ERP system, e.g. SAP® |

cached in the tester or network transfer to PC, PLC, MES, ... transfer to ERP system, e.g. SAP® |

| — | — |

with ERP, MES, PLC, CAQ, ... via LAN, WWW, OPC, ... |

with ERP, MES, PLC, CAQ, ... via LAN, WWW, OPC, ... |

with ERP, MES, PLC, CAQ, ... via LAN, WWW, OPC, ... |

with ERP, MES, PLC, CAQ, ... via LAN, WWW, OPC, ... |

| — | yes - via PC-Software | yes | yes | yes | yes |

| — | — | yes | yes | yes | yes |

| — | yes | yes | yes | yes | yes |

| yes | yes | yes | yes | yes | yes |

| — | — | yes | yes | yes | yes |

| — | yes | yes | — | — | — |

| SCHLEICH embedded | SCHLEICH embedded | Windows Embedded®-PC in the tester | Windows Embedded®-PC in the tester | — |

Windows 10®-19"-Industrial PC integrated Stand-alone Windows 10®-PC |

| — | — | — | — | external Windows 10® PC | — |

| LED 7-segment | touch color LCD 480 x 272 |

touch color LCD 800 x 480 PC monitor of any size |

touch color LCD 800 x 480 PC monitor of any size |

— | PC monitor of any size |

| — | — | — | — | touch monitor of any size | — |

| on stock | in 10 business days | on stock | order-related manufacturing | order-related manufacturing | order-related manufacturing |

SCHLEICH is a leading manufacturer of electrical safety, functional, winding and electric motor testing technology.

SCHLEICH is a world-renowned company that focuses on the development of innovative products in the field of testing technology for electrical products of all kinds.

From A to Z - everywhere SCHLEICH testing technology is in use worldwide. Our customers come from over 50 countries and regions. Everything is developed and produced in Germany.

Quality work - Made in Germany.

2022 - SCHLEICH is awarded for the fifth time as TOP100-Innovator

2016 - SCHLEICH released the first VoltageAnalyzer for measuring the real voltage directly at the winding terminals

2012 - SCHLEICH is awarded as TOP100-Innovator for the first time

2005 - SCHLEICH released the first stator tester with partial discharge test

1995 - SCHLEICH integrates touch-displays into testing devices as a world leader

1990 - SCHLEICH released the first safety and function tester with fully automatic integrated test terminal changeover

1987 - SCHLEICH released the first surge tester with PC-control under DOS and fully automatic integrated test terminal changeover

1985 - SCHLEICH released the first MotorAnalyzer

1982 - SCHLEICH focuses fully on electrical test engineering of electrical products

1952 - SCHLEICH is founded as a motor repair shop

Pioneering spirit, competence, curiosity, brand new technologies and innovations. This is what the 145-strong SCHLEICH team stands for - led by Martin & Jan-Philipp Lahrmann. Father & son. Your guarantors for long-term partnership.