MTC3

Winding tester fully automatic for automation, laboratory ...

You expect test technology unlimited.

The MTC3 is the TOP class of the winding test technology.

Your plus in test accuracy, precision, versatility, profitability and speed.

Flexible, intuitive and yet uncomplicated.

Product consultant

Key-Facts

Surge voltage in perfection.

- Inspection of stators, rotors, transformers and chokes

- Shortest rise time 60 ns

- Fully-integrated partial discharge test according to IEC 61934 and DIN EN 60034-18-41

- Resistance measurement in 4-wire technology with temperature compensation

- Insulation resistance test with automatic PI-measurement

- Inductance test | LCR-inductance measuring bridge

- High-voltage test AC according to VDE-standard

- Partial discharge HVAC

- Insulation test DC

- Precise 4-wire resistance test with temperature compensation up to µΩ-range

- Rotary field test with static probe

- Expandable up to 150 connections

- Temperature probe test for 1, 2, 3 … x probes

- Automatic test with subsequent Go/ NoGo – comparison

- Fast & precise measurements with the latest DSP-Technology (Digital Sensor Processor)

- High-resolution measurements for all test methods

- Freely-programmable in- & and outputs

- Switch matrix modules for all types of test methods

- PLe, SIL3, Kat4 Safety circuit (depending on device variant and degree of risk)

- High process reliability

- Switching matrices for all types of test methods

- PLe, SIL3, Kat4 safety circuit

- High process reliability

- Integrated high-quality industrial-PC with Windows®7 or Windows®10

- Central database for millions of test squences and results -SQL-server

- Extensive statistical analyses – Trending, Gaussian distribution, FPY…

- Traceability for all test object´s components

- User administration

- Configurable test report printout

- Freely configurable label print for thermal transfer printers

- Several label printers addressable

- Reading of any 1D- and 2D-barcodes

- Remote control: RS232, SPS, Profibus, Profinet, CAN, DeviceNet, Ethernet, EtherCat, USB…

- Full network connectivity

- Data exchange with ERP- and CAQ-systems

- Connection to MES-systems

- Ideal OEM-conditions for easy integration in automatic lines

- Remote maintentance and remote calibration possible

Description

Test technology 4.0

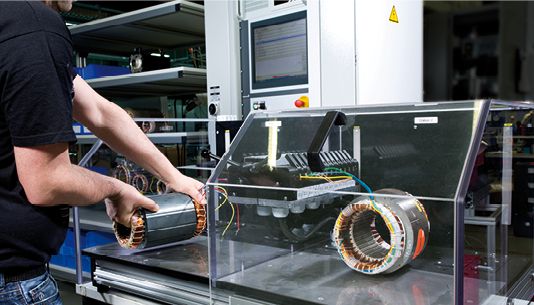

Thanks to the patented SCHLEICH surge voltage test the fully-automatic MTC3-stator testers inspect your windings for possible insulation faults in a fast and reliable way.

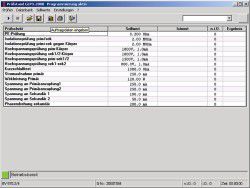

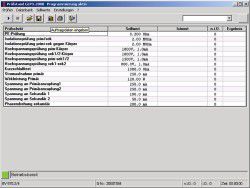

As soon as the test object has been connected, the test starts to run and the connections and test methods are automatically switched over. The MTC3 evaluates every single test step. At the end of the entire test run it generates a clear and reproducible GO/ NOGO statement.

For measuring, controlling and saving purposes we always insisted on the integration of PCs in our winding testers. By using the proven Microsoft®-technology we are able to offer a clear test result overview to the operator and a variety of input- and configuration possibilities for the installation personnel.

Numerous statistical analyses support your quality assurance. Thanks to the variety of possible reports you can demonstrate your proven quality to your customers.

The MTC3 testers are manufactured according to your requirements and requested number of winding connections. For the stator test, we can easily integrate all requested test methods totally according to your requirements. It makes no difference if you require a manual or automatic single-, double- or multi test station, which is delivered either with or without test cover or table. Tests in automated production lines are also possible with our MTC3-testers.

Thanks to the great flexibility of soft-and hardware it is possible to provide a cost-effective tester which fulfills all your expectations.

Test capabilities

The MTC3 is controlled by the integrated industrial PC. The software allows full-, semi-automatic and manual inspections. In case a fault in the test object is to be determined and located, the tester provides the manual single tests. Thus, the MTC3 offers clearly more than a standard tester for series production.

1. Fully-automatic test

The test sequence consists of several single test steps. Each test step consists of a test step (e.g. surge voltage) as well as set values and tolerances. After switching on the tester the single test steps are fully-automatic run one after another and without interruption. At this, each test step is automatically evaluated and the overall result is displayed at the end of the test.

At testers with e.g. 6 winding connections the tester automatically switches between these connections. This is the precondition for the automatic test run.

2. Semi-automatic test

The test sequence consists of several single test steps. Each test step consists of a test step (e.g. surge voltage) as well as set values and tolerances.

After switching- on the tester, the operator selects the test step to be run. He may, for example, contact the lamellas of an armature with test probes and start the test with this test step.

The tester displays the current measured value in large digits in the lower part of the screen. As soon as the operator presses a button, the set values are automatically compared with the measured values and immediately evaluated. Afterwards the operator selects another test step and so on until test results from all test steps are available. The test steps may even be repeatedly tested. It´s also possible too interrupt the test sequence and continue at a later time.

The semi-automatic test is based on a pre-defined test sequence with fixed test steps, set values and tolerances, which, however, may be manually carried out by the operator in any arbitrary order.

3. Manual test

There´s no specified test sequence.

The operator accesses single test methods (e.g. surge voltage- or resistance test…)and switches the test method to any arbitrary connection clamp of the test object.

During the test, the measured values are displayed in large digits. As soon as the test is finished, the measured value is taken-over in a summary of all measured values.

The operator may also run single measurements, as if he had single testers for each test method, and collect the results in a summary. The results may then be saved and printed.

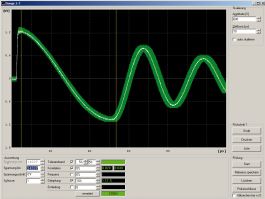

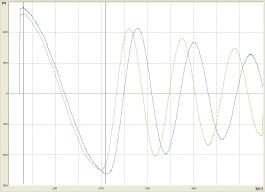

Evaluation of surge voltage

| Tolerance band method | The surge wave has to be within a programmable tolerance band. |

| Patented Correlation method | The relation between reference surge wave and currently measured surge wave is automatically determined and the deviation is indicated in %. |

| Error area (EAR) | The error area between reference surge wave and currently measured surge wave is automatically determined and the deviation is indicated in %. |

| Difference in area | The area difference between reference surge wave and currently measured surge wave is automatically determined and the deviation is indicated in %. |

| Attenuation method | The deviation in the attenuation course between reference surge wave and currently measured surge wave is automatically determined and indicated in %. |

| Frequency method | The difference in frequency between reference surge wave and currently measured surge wave is automatically determined and indicated in %. |

| Automatic phase comparison | The tester automatically measures the 3 connection combinations of a DC winding and indicates the 3 surge waves in different colors on the screen. |

Technology

Automation and Interfaces.

- digital I/O, (input/output 24 V to PLC)

- RS232 via SCHLEICH communication protocol

- LAN via SCHLEICH communication protocol

- LAN via TCP/IP

- USB

- PROFIBUS

- PROFINET

- EtherCAT

- CANopen

- CAN-Automotive

- DeviceNet and more …

- individual special solution …

Benefits of measurement technology at a glance.

Connections

- Standard model: 3 plus laminated core (ground connection)

- Optional: up to 24 connections

- All connections freely programmable via matrix

Measuring technology

- Precise and fast measurements

- TRMS – true R.M.S. measurement

- R.M.S.- and peak value measurement

Autotest

- automatic stator-, and motor inspection

- fully-automatic fault analysis

Surge voltage

- 6 kV or 15 kV

- Automatic and manual surge voltage test

- Automatic evaluation

- 8 different evaluation methods incl. correlation (SCHLEICH-patent)

High-voltage DC

- 6 kV or 15 kV

- Manually adjustable

- Automatic programmable

- Step voltage measurement

Insulation resistance DC

- 6 kV or 15 kV

- According to VDE 0701

- 1 MΩ – 100 GΩ

Polarization index

- 6 kV or 15 kV

- PI-measurement

- DAR-measurement

- Automatic measurement

Partial discharge surge – option

- 6 kV or 15 kV

- According to DIN EN 60034-18:2014

- Measurements of

- PDIV – Partial discharge inception voltage

- RPDIV – Repetitive partial discharge inception voltage

- RPDEV – Repetitive partial discharge extinction voltage

- PDEV – Partial discharge extinction voltage

- Measurements via coupler in the test lead- perfect for motors

- Measurements via antenna – perfect for stators

Resistance- Option

- 1 μΩ – 100 kΩ

- imbalance inspection

- Precise 4-wire technology

- ambient temperature compensation

- object´s temperature compensation

- temperature sensor test

High-voltage AC – Option

- Up to 6 kV, up to 1 A

Partial discharge HVAC – Option

- Up to 6 kV, up to 1 A

- Measurement between phases (dependent from the test object´s switching mode)

- Measurement between phases and laminated core

Rotary field- Option

- Rotary field test with static test probe

- For 1- and 3-phase-motors

- For pole-changeable motors

- Suitable for segregated windings

Inductance- Option

- Inductance measurements via integrated measuring bridge

- 4-wire technology

Impedance – Option

- Impedance measurement via integrated measuring bridge

- 4-wire technology

Capacity – Option

- Capacity measurement via integrated measuring bridge

- 4-wire technology

PE/ Ground AC – Option

- PE/Ground resistance, measured with AC

- 10 –200 A AC, adjustable, electronically controlled

- Current steps 1 A

- 6, 12, 18, 24 V AC

⇒ Find more details under Downloads.

Applications

Pioneer in functionality and measuring accuracy.

MTC3 with dual test cover

- 4-wire contacting with central handle for opening all clamps at the same time

- VA-plate to contact the stator

MTC3 to inspect larger stators

MTC3 in a production line

- Fully-automatic line

- Fully-automatic contacting

- Communication with PLCs

- Communication with ERP-systems

MTC3 with mounted dual test cover

- Dual test station for compressors

- Solid industrial test cover – designed for millions of moves – no plastic construction- solid aluminium frame with longlife-linear guide

Dual test table

- Dual test cover for compressors

- Solid longlife-industrial test cover- no plastics

Contacting

- Integrated 4-wire clamps in the front

- Result light on both sides of the clamps

MTC3 use in electric workshop for rail drives

- Inspection of free-standing stators

- If requested, manual inspection with test probes

- 2- hand start

- 4-wire measuring technology

Accessories

Kelvin Clamps

High-precision resistance measurement even for smallest resistances- condition for high-precise resistance measurements

- solid industrial quality

- 3 different sizes

Terminal blocks

Modular terminal blocks to contact loose lead ends- stackable 4-wire clamps

- modular design

- different designs and sizes

Pneumatic clamps

Automatic pneumatic quick clamping- automatic clamp with pneumatic cylinder

- push-button for fast release

- for different wire diameters

- hole diameter with 4, 6 or 9 mm

Motor Terminal Plugs

Test plugs for contacting motor terminal boards- induction motor test plugs / motor terminal board plugs

- quick contact for 6, 8 or 9 bolts

- for different motor terminal board sizes

- for threaded bolts M4, M5, M6, M8 and M10

- without, with 1 or 2 motor grounding tips

- super simple test lead connection

- 4 patents pending

Single Test Covers

Testing with protection against accidential contact- various sizes

- ergonomic – smooth-running – versatile

- sturdy industrial quality – long service life

- up to Performance Level PLe

- built-in result lights

- plenty of space for adapter installations

- optional: automatic opening – guard locking …

Safety Barriers

For securing the testing area- mobile workplace protection

- with integrated emergency stop, warning lights

- built-in 2-hand start

analyzer

PC-Software for statistical analysis of test results- in-depth test result analysis

- production online monitoring

- informative statistics-report printout

Barcode Scanner

Scanning of serial numbers, product types, production specifications, ...- various 1D & 2D-barcode scanners

- reading of order data, operator names, serial numbers and more

Label Printers

Label printing of type plates, device and test result decals, ...- various thermal transfer printers

- printout with order data, serial number, and more

Rotary field probes

Rotary field measurement of rotating machines- contact-free rotary field measurements at stators

- over 10 different models

- fully-electronic without moving parts

Custom-made test covers

Test covers – individually designed and crafted to meet your specifications- individual customer-specific solutions of any kind, application and size

Safety-Light Curtains

Testing without protection against accidental contact- 1-, 2-, 3- or 4-sided open and monitored

- two-channel monitoring of safety

- for large or bulky test objects

- accessible by pallet jack

- marking of the approved test area

- installation of contacts and clamps

- various sizes

- custom solutions …

Special contactings

Customized solutions based on the modular SCHLEICH building kit- individual solutions

- for perfect 4-wire measurement

- float-mounted collets

Warning lights

Warning and indication of hazardous test voltage- warning of hazardous test voltage

- only required for touchable test objects

- not necessary when test cover is used

Result Lights

Test result pass or fail- what is the test result?

- green: go – pass – OK

- red: no go – fail – not OK

Two-Hand Operation

Protection against electrical hazards- dual-circuit safety with BG-approval

- solid and stable

- 2 different models

Test dummy, self-test black box

Dummy test used for standardized functionality control- for daily inspection

- universal blackboxes

- factory calibration, also according to DAkkS

Calibration Resistors

High precision for verifying measurement accuracy- precision resistors for the annual calibration

- low drift

- factory calibration

- DAkkS calibration (optional)

High-Voltage Relays

Switching and disconnecting high voltages safely- high-voltage relays

- switch matrixes

- safe isolation

- with single or double changeover contacts

- SPDT “Single Pole Double Throw”

- for rail mounting DIN50022

- system components for DIY

High-Voltage Cables

Safe conducting and distribution- for a variety of applications

- cables up to 100 kV

Downloads

International PDFs

- Brochure MTC3

- Brochure Test covers | test cabins | protection devices

- Motor and winding testers » Product overview

- Comprobadores de motores eléctricos y bobinados » Descripción de productos

- Testeurs pour moteurs électriques et bobinages » Guide produits

- SCHLEICH » Company brochure

German PDFs

For further information please do not hesitate to contact our technical sales under:

- +49 2372 901 25 40

- Email request

print preview

Product comparison

| type of tester |

| surge test |

| resistance |

| Induktivitäts-Kapazitätsprüfung |

| PE/GB |

| insulation |

| polarization index |

| high voltage AC |

| high voltage DC |

| partial discharge |

| function AC 1-phase |

| function AC 3-phase |

| sense of rotation |

| test terminals |

| test cover |

| automation |

| database |

| test plans |

| test results |

| communication |

| test report print-out |

| label print-out |

| scanner port |

| password protection |

| user management |

| operating system |

| display |

| battery mode |

| delivery |

|

|

|

|

|

|

|

|

|

|

|

| MTC2 R7 | MotorAnalyzer1 | MotorAnalyzer2 R2 | MTC2 | MTC3 | VoltageAnalyzer | GLP3-M | EncoderAnalyzer | Dynamic MotorAnalyzer | PortaTest | Winding Machines |

|

THE surge tester · normative partial discharge · resistance · 4 wire measurement · Windows 10|11® · test report · PDF printing · network … |

motor Service · repairs · troubleshooting · maintenance · servicing · battery operation · PC software … |

multitool · 15 test methods · surge voltage 3 kV · resistance · inductance · capacitance · motor service · repair · fault detection · maintenance · battery mode · PC software … |

THE surge tester – up to 50 kV – plus normative partial discharge – resistance – 4-wire measurement – Windows10® – test protocol – PDF printing – network … |

Uncompromising ALL-IN-1 winding test for production · for all standard and special motors · for automotive drives · for coils of all kinds · automation · in-line partial discharge testing – worldwide networking · central data storage … |

high-precision test probe – direct surge voltage measurement at the winding – partial discharge – passive / active microwave antenna – up to 6 kV … |

modular ALL-IN-1 engine test system · no limits · customer specific · VDE/EN/UL/IEC … · production · automation · global networking · databases · statistics · data import/export · Windows® · complex systems … |

encoder and resolver testing/adjustment · encoder signal analysis · encoder power supply: 3 – 30 V · interface: HIPERFACE – EnDat – SSI – BiSS · BEMF measurement · repair · motor service · encoder production · servo motor production … |

online monitoring · fault analysis on the running motor · for mains and frequency converters · over 100 measured values · speed · torque · efficiency · unique oscilloscope · data recorder · trend analysis · battery operation · outdoor … |

insulation oil testing ⋅ fully automatic ⋅ dielectric strength ⋅ mobile ⋅ portable ⋅ on-site testing ⋅ laboratory testing ⋅ test voltages: 60 kV – 80 kV – 100 kV ⋅ various electrodes ⋅ integrated international test standards … |

coil winding machines for electric motors · for repair · for motor production · standard machines · special solutions … |

| read more | read more | read more | read more | read more | read more | read more | read more | read more | read more | read more |

|

surge testers winding testers |

winding testers motor & winding testers ALL-IN-1 |

surge testers winding testers motor & winding testers ALL-IN-1 |

surge testers winding testers |

surge testers winding testers |

— | electric motor testers ALL-IN-1 | encoder/resolver testers | electric motor testers ALL-IN-1 | insulating oil testers | winding machines |

|

0–6 kV 0–12 kV 0–15 kV |

— | 0–3 kV |

0–6 kV 0–12 kV 0–15 kV 0–25 kV 0–30 kV 0–40 kV 0–50 kV |

0–6 kV 0–15 kV |

0–6 kV | 0–6 kV | — | — | — | — |

| 4-wire measurement | 4-wire measurement | 4-wire measurement | 4-wire measurement | 4-wire measurement | — | 4-wire measurement | — | — | — | — |

|

nein ja |

— | — | — | — | — | — | — | — | — | — |

| — | — | — | — |

1–10 A˜ 6/12 Veff 1–30 A˜ 6/12 Veff |

— |

1–10 A˜ 6/12 Veff 1–30 A˜ 6/12 Veff custom |

— | — | — | — |

| Vmax like surge test | 0–3 kV ˭ | 0–6 kV ˭ | Vmax like surge test | Vmax like surge test | — |

0–1 kV ˭ max. 250 GΩ custom |

— | — | — | — |

| Vmax like surge test | Vmax like insulation test | Vmax like insulation test | Vmax like surge test | Vmax like surge test | — | — | — | — | — | — |

| 0–6 kV˜ max. 100 mA | — | — | 0–6 kV˜ max. 100 mA |

0–3 kV˜ max. 100 mA 0–6 kV˜ max. 100 mA 0–6 kV˜ max. 200 mA 0–6 kV˜ max. 1 A custom |

— |

0–3 kV˜ max. 100 mA 0–6 kV˜ max. 100 mA 0–6 kV˜ max. 200 mA custom |

— | — | — | — |

| 0–4 kV ˭ | 0–6 kV ˭ | — | custom | — | — | — | — | |||

| in case of surge test | — | — | in case of surge test |

in case of surge test in case of high voltage test AC in case of surge voltage and high voltage |

in case of surge test |

in case of surge test in case of high voltage test AC in case of surge voltage and high voltage |

— | — | — | — |

| — | — | — | — | — | — | according to your requirements | — | — | — | — |

| — | — | — | — | — | — | according to your requirements | — | according to your requirements | — | — |

| yes | yes | yes | yes | yes | — | yes | — | — | — | — |

|

T1, T2, T3, frame T1, T2, T3, Y, frame K1, K2, frame |

T1, T2, T3, frame | T1, T2, T3, frame |

T1, T2, T3, frame T1, T2, T3, Y, frame K1, K2, frame |

T1, T2, T3, frame T1, T2, T3, Y, frame 3, 6, 9, 12, 15, 18, ..., frame |

T1, T2, T3 |

L1, L2, L3, N, PE made to your specifications |

— | — | — | — |

| possible | — | — | possible | possible | — | possible | — | — | — | — |

|

with digital I/O with RS232 via SCHLEICH communication protocol with LAN via SCHLEICH communication protocol |

— | — |

with digital I/O with RS232 via SCHLEICH communication protocol with LAN via SCHLEICH communication protocol |

with digital I/O with RS232 via SCHLEICH communication protocol with LAN via SCHLEICH communication protocol with LAN via TCP/IP Socket Communication with PROFIBUS with PROFINET with EtherCAT with DeviceNet made to your specifications |

— |

with digital I/O with RS232 via SCHLEICH communication protocol with LAN via SCHLEICH communication protocol with LAN via SCPI commands with PROFIBUS with PROFINET with EtherCAT with CANopen with CAN Automotive with DeviceNet made to your specifications |

— | — | — | — |

|

ACCESS SQL |

— | — |

ACCESS SQL |

ACCESS SQL |

— |

ACCESS SQL ORACLE |

— | — | — | — |

|

stored in the tester stored in the tester and network import from PC, PLC, MES, ... |

— | — |

stored in the tester stored in the tester and network import from PC, PLC, MES, ... |

stored in the tester stored in the tester and network import from PC, PLC, MES, ... |

— |

stored in the tester stored in the tester and network import from PC, PLC, MES, ... |

— | — | — | — |

|

cached in the tester or network transfer to PC, PLC, MES, ... |

cached in the tester | cached in the tester |

cached in the tester or network transfer to PC, PLC, MES, ... |

cached in the tester or network transfer to PC, PLC, MES, ... |

— |

cached in the tester cached in the tester or network transfer to PC, PLC, MES, ... |

— | — | — | — |

|

with ERP, MES, PLC, CAQ, ... via LAN, WWW, OPC, ... |

— | — |

with ERP, MES, PLC, CAQ, ... via LAN, WWW, OPC, ... |

with ERP, MES, PLC, CAQ, ... via LAN, WWW, OPC, ... |

— |

with ERP, MES, PLC, CAQ, ... via LAN, WWW, OPC, ... |

— | — | — | — |

| yes | yes - via PC-Software | yes - via PC-Software | yes | yes | — | yes | — | yes | — | — |

| yes | — | — | yes | yes | — | yes | — | — | — | — |

| yes | — | — | yes | yes | — | yes | — | — | — | — |

| yes | — | yes | yes | yes | — | yes | — | yes | — | — |

| yes | — | — | yes | yes | — | yes | — | yes | — | — |

| Windows 10 11®-PC in the tester | SCHLEICH embedded | SCHLEICH embedded | Windows 10®-PC in the tester | Windows 10®-19"-Industrial PC integrated | — | Windows 10®-19"-Industrial PC integrated | — | Windows 10®-PC in the tester | — | — |

| PC monitor of any size | LCD 120 x 80 | touch color LCD 480 x 272 | PC monitor of any size | PC monitor of any size | — | PC monitor of any size | — | — | — | — |

| — | yes | yes | — | — | — | — | — | yes | — | — |

| on stock | on stock | on stock | on stock | order-related manufacturing | order-related manufacturing | order-related manufacturing | order-related manufacturing | order-related manufacturing | order-related manufacturing | order-related manufacturing |

SCHLEICH is a leading manufacturer of electrical safety, functional, winding and electric motor testing technology.

SCHLEICH is a world-renowned company that focuses on the development of innovative products in the field of testing technology for electrical products of all kinds.

From A to Z - everywhere SCHLEICH testing technology is in use worldwide. Our customers come from over 50 countries and regions. Everything is developed and produced in Germany.

Quality work - Made in Germany.

2022 - SCHLEICH is awarded for the fifth time as TOP100-Innovator

2016 - SCHLEICH released the first VoltageAnalyzer for measuring the real voltage directly at the winding terminals

2012 - SCHLEICH is awarded as TOP100-Innovator for the first time

2005 - SCHLEICH released the first stator tester with partial discharge test

1995 - SCHLEICH integrates touch-displays into testing devices as a world leader

1990 - SCHLEICH released the first safety and function tester with fully automatic integrated test terminal changeover

1987 - SCHLEICH released the first surge tester with PC-control under DOS and fully automatic integrated test terminal changeover

1985 - SCHLEICH released the first MotorAnalyzer

1982 - SCHLEICH focuses fully on electrical test engineering of electrical products

1952 - SCHLEICH is founded as a motor repair shop

Pioneering spirit, competence, curiosity, brand new technologies and innovations. This is what the 145-strong SCHLEICH team stands for - led by Martin & Jan-Philipp Lahrmann. Father & son. Your guarantors for long-term partnership.