The entry-level device for your motor service

Compact design and a wide range of applications for troubleshooting in windings that are not live are the distinguishing features of this tester.

Ten reliable tests and test methods are built in. Due to its integrated rechargeable battery, tests can also be performed off-grid, without a power connection. It is a versatile tool for electrical engineering, motor repair, maintenance and servicing.

Our MotorAnalyzer1 is a universal tester for electric motors and winding goods. It unites ten different test methods in one user-friendly and portable device. The combination of test methods, its ultra-compact design and the battery powered operation make the MotorAnalyzer1 the perfect tool for on-site use – particularly in difficult mounting locations.

To test an electric motor, the three winding leads and the motor housing are wired to the tester. The surge voltage and resistance tests are set in motion automatically. Subsequently, the motor is submitted to a high-voltage test in order to assess the quality of the motor in a fast and accurate manner.

MotorAnalyzer1 was designed for both in-house and on-site use. Off-grid battery mode lets you test electric motors (e.g. on a crane) accurately even in complex mounting locations. With MotorAnalyzer1 the user will have the ability to make a definitive GO/NOGO-assessment using all built-in test methods and advanced software diagnostics with superior visual support on-screen.

Power supply

Autotest

Surge voltage

Resistance

Insulation resistance

Polarization index

High voltage DC

PE/GB-resistance

“Neutral zone” in DC motors

Rotary field

Winding fault location

⇒ Find more details under Downloads.

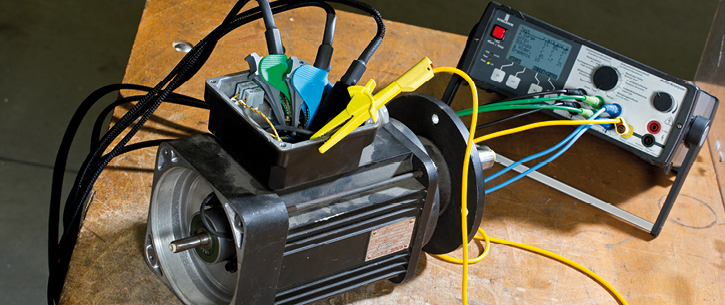

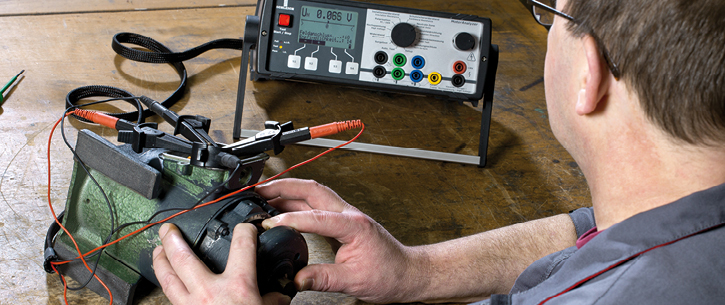

Motor inspection in the workshop.

A useful test method is the autotest. It shows an overview of all test results in a single fully automatic test run.

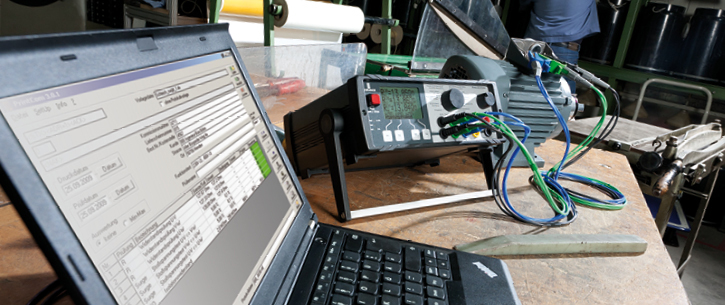

Testing of a motor and transfer of test results to a PC.

Alltest data is saved on the PC and subsequently printed.

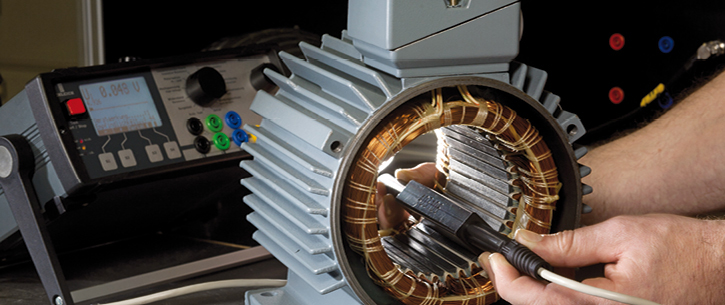

Fault detection of a turn-to-turn fault.

The probe is used to test each slot.

If a turn-to-turn fault is present, a deviation has to be traceable in two slots, since the coil with a turn-to-turn fault leads through two slots.

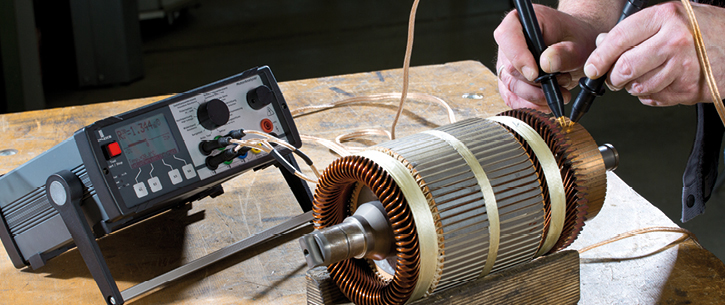

Turn-to-turn fault testing at a rotor

Resistance test using two four-wire measurement probes.

Both test probes, each housing two measuring contacts, are pressed against two bars of the rotor. As the test probes are moved from bar to bar, each respective resistance measurement is detected.

High-voltage test at a motor between winding and frame or between single windings or to a temperature sensor.

„Neutral zone“-adjustment of a DC motor.

The brush bridge is rotated until the neutral zone is detected precisely. The MotorAnalyzer automatically displays the directional deviation indicating in which direction the operator must turn the carbon brush.

Für weitergehende Informationen steht Ihnen unser technischer Vertrieb auch gerne telefonisch zur Verfügung.