Test tables with rollers

Mobile test equipment use in your shop floor

Product consultant

Key-Facts

Mobility counts.

- Solid, mobile, perfect for workshops

- Height-adjustable table top and bottom

- Height-adjustable and fully-extensible drawers

- Height-adjustable holder for test probes

- Horizontal or sloped table top

- Sloped table top with horizontal front, e.g. for a keyboard

- Optional with test probe holder

- Optional with safety test pistol holder

- Optional with LED- warning lights in the frame

- Delivered completely assembled for immediate use

- Roller tables and driving carriages by company hera

Description

Everything on hand – no problem with the roller table.

The roller table is ideally-suited for transporting testers or testers combined with test cover in production.

It´s very solid, stable and made from aluminium profiles which make it easy to roll it from tester to tester, even under rough working conditions.

The high and stable rubber rollers assure a good mobility. All rollers are steerable and eqipped with brakes, to be activated with by the foot.

Additionally the roller tables may be equipped with fully-extendable drawers to store adapters, tools, documentation, and so on.

Technology

All benefits at a glance.

The modular heavy duty roller table

|

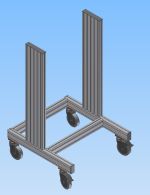

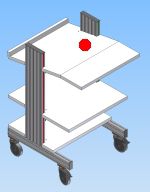

Roller table | Basic rack

The roller table has a modular construction. As basis serves the basic rack, all further components are added.

|

|

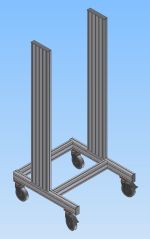

Basic rack + extended side struts

The side struts may be extended upwards. This is especially useful if a test cover and a tester is installed in the rack at optimum viewing height (above the test cover).

|

|

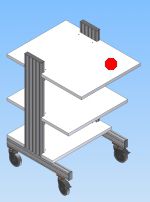

Basic rack+ horizontal table top XL

The basic rack is equipped with a horizontal table top (size XL). By means of the optional push handle (4000959) at the table´s front side, the table may easily be moved, pushed and pulled. The table top is continuously adjustable in height. Thus you are able to adjust the table at the optimum working position. NOTE: The table top is marked with a red dot in the picture.

|

|

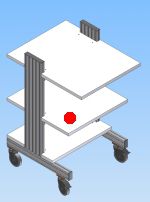

Basic rack+ sloping table top XL

The basic rack is equipped with a 3/4 sloping table top, size XL. By means of the optional push handle (4000959) at the table´s front side, the table may easily be moved, pushed and pulled. The table top is continuously adjustable in height. Thus you are able to adjust the table at the optimum working position. NOTE: The table top is marked with a red dot in the picture.

|

|

Basic rack + horizontal table top, size L

The basic rack is equipped with a horizontal table top (size L). The table top is continuously adjustable in height. Thus you are able to adjust the table at the optimum working position. NOTE: The table top is marked with a red dot in the picture.

|

|

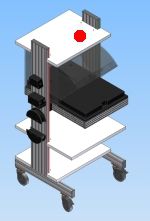

Basic rack + horizontal table top, size M with 2 cable passages

The basic rack is equipped with an horizontal table top (size M). Both sides of the table top have an integrated cable passage. Thus, the table top is ideally suited for placing a tester, a printer or a screen on it. The table top is continuously adjustable in height. Thus you are able to adjust the table at the optimum working position. NOTE: The table top is marked with a red dot in the picture.

|

|

Basic rack + cable winder on left/ right side

The basic rack is equippable with a cable winder. On this winder, e.g. long leads may easily be winded. The single winders are continuously adjustable in height. Thus you are able to adjust the winders at the optimum working position. NOTE: The cable winder is marked with a red dot in the picture. |

|

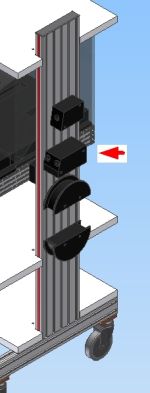

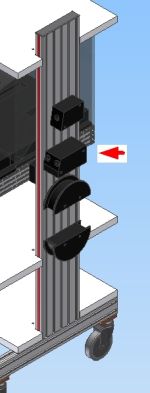

Basic rack+ holder for HV-test probes (right side)

The basic rack is equippable with a holder for two HV-test probes. Two test probes may comfortably be placed there. The holder is continuously adjustable in height. Thus you are able to adjust it at the optimum working position. NOTE: The holder is marked with a red dot in the picture. |

|

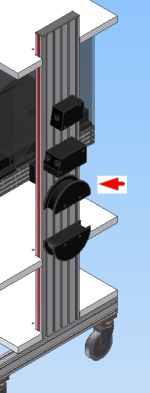

Basic rack + holder for PE-test probe (right side)

The basic rack is equippable with a holder for a PE-test probe. The holder is continuously adk´justable in height. Thus you are able to adjust it at the optimum working position. NOTE: The holder is marked with a red dot in the picture. |

|

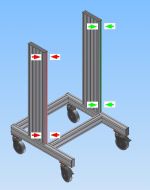

Basic rack+ integrated warning lights (LED) in the struts (0,9 m)

The basic rack is equippable with warning LED-lights. By this, it is clearly indicated, if a test object is connected to voltage or if it´s voltage-free. The LED-stripes are located in the basic rack´s slots. NOTE: Both positions of the LED-stripes are marked with green and red arrows in the picture. |

Applications

Impressions

|

Standard-roller table

|

|

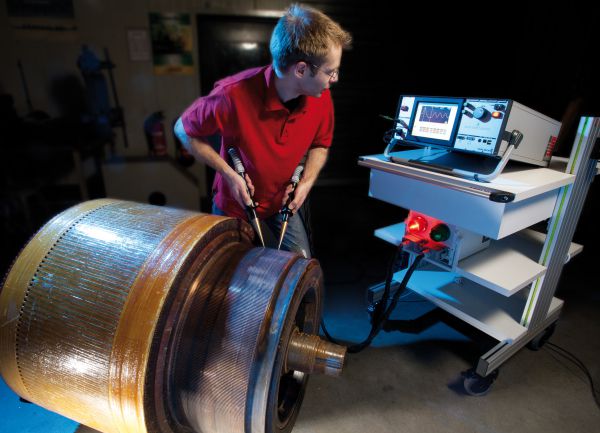

Heavy duty roller table

|

|

Heavy duty roller table

|

|

Heavy duty roller table

|

|

Heavy duty roller table

|

|

Heavy duty roller table

|

|

Cable winder at the heavy duty roller table

|

|

Test probe at heavy duty roller table

|

Downloads

International PDFs

German PDFs

For further information please do not hesitate to contact our technical sales under:

- +49 2372 901 25 40

- Email request

print preview

SCHLEICH is a leading manufacturer of electrical safety, functional, winding and electric motor testing technology.

SCHLEICH is a world-renowned company that focuses on the development of innovative products in the field of testing technology for electrical products of all kinds.

From A to Z - everywhere SCHLEICH testing technology is in use worldwide. Our customers come from over 50 countries and regions. Everything is developed and produced in Germany.

Quality work - Made in Germany.

2022 - SCHLEICH is awarded for the fifth time as TOP100-Innovator

2016 - SCHLEICH released the first VoltageAnalyzer for measuring the real voltage directly at the winding terminals

2012 - SCHLEICH is awarded as TOP100-Innovator for the first time

2005 - SCHLEICH released the first stator tester with partial discharge test

1995 - SCHLEICH integrates touch-displays into testing devices as a world leader

1990 - SCHLEICH released the first safety and function tester with fully automatic integrated test terminal changeover

1987 - SCHLEICH released the first surge tester with PC-control under DOS and fully automatic integrated test terminal changeover

1985 - SCHLEICH released the first MotorAnalyzer

1982 - SCHLEICH focuses fully on electrical test engineering of electrical products

1952 - SCHLEICH is founded as a motor repair shop

Pioneering spirit, competence, curiosity, brand new technologies and innovations. This is what the 145-strong SCHLEICH team stands for - led by Martin & Jan-Philipp Lahrmann. Father & son. Your guarantors for long-term partnership.