Dynamic MotorAnalyzer

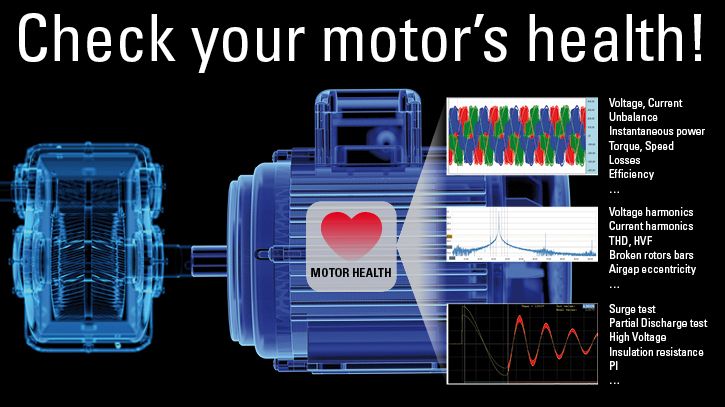

Check your motor's health!

Dynamic motor analysis allows you to check your running motor in its working environment. The Dynamic MotorAnalyzer measures the electrical parameters and can calculate mechanical parameters from these measurements.

With the Dynamic MotorAnalyzer you can check the mains supply, internal conditions and load conditions of your motor. An analysis of the entire electric motor is performed based only on the 6 electrical measured values (3 x U, 3 x I).

As a supplement to the MotorAnalyzer1, MotorAnalyzer2 R2 and the MTC2 winding testers, the Dynamic MotorAnalyzer completes your test device portfolio.

Product consultant

Key-Facts

All in One – Motor analysis.

- Power Quality Analysis

- Motor Quality Analysis

- Motor Load Analysis

- Professional motor analysis without special knowledge required from the operator

- Perfect for trouble shooting at the mains or frequency converters

- Perfect for trouble shooting at electric motors

- Perfect for trouble shooting at the mechanical load

- Perfect for preventive maintenance

- Determination of mechanical power parameters and torque

- Trend analysis, Forecast

- Long-term analysis

- Motor start-up analysis

- Efficiency analysis

- Capacity-analysis

- Energy costs analysis

- Continous real time long-term measurements, measured values are constantly displayed

- Direct voltage measurement up to 700 Veff

- Indirect voltage measurement via PTs up to 50 kV

- Current clamp measuring ranges from 5 – 5.000 Aeff

- Current measurement via CTs up to 10 KAeff

- Integrated oscilloscope function to assess voltages, currents and powers…

- Switch-over to country-specific units as e.g. Nm, lb-ft, HP, KW and other

- Data base to store test results

- Extensive, self-configurable printing report

- Battery-operation

- Worldwide voltage supply 90 – 250 V / 47 – 63 Hz

Description

Professional motor analysis – no technical expertise required.

The dynamic motor analysis allows the inspection of a running motor in its working environment. For this, the electrical parameters of mains supply and motor are measured and, among others, the corresponding mechanical parameters are calculated. The aim is to receive an analysis of the electric motor, its mains supply and its load conditions – only based on 6 electrical measured values ( 3x voltage and 3x current).

The Dynamic MotorAnalyzer significantly simplifies the motor inspection- without requiring special knowledge or skills from the operator. It is the perfect supplement to our SCHLEICH- winding testers MotorAnalyzer2 and MTC2.

Dynamic motor analysis in practice.

It often occurs that motors are operated under overload conditions or fail due to unknown reasons. This may be due to the mains supply, the motor itself or its load. The error may result from electrical or mechanical reasons.

It is often hard to detect the error cause as motors are often part of a complex plant or as it is installed in plants with difficult access.

In most cases the motor lead in the motor´s control cabinet is easier to access. Here is the perfect place to measure the 6 electrical values (3x U and 3x I). By means of a variety of analyzing methods the Dynamic MotorAnalyzer evaluates the motor´s condition. It is also possible to speak about the motor´s “health condition”.

This makes the Dynamic MotorAnalyzer an easy-to-use measuring tool for detecting complex problems within the machine´s system. Basically it is always better to determine the origin error cause before repairing or exchanging the motor. In case the problems are not properly detected the electric motor is likely to fail again. This would cause even more downtime- and repair costs, which should be avoided in any case.

Typical measurements with the Dynamic MotorAnalyzer

The Dynamic MotorAnalyzer not only supports you in finding typical erros, but also in finding those ones which are rather difficult to detect and then to solve the problem afterwards. For this, it uses the latest methods and technologies regarding MCSA (MCSA – Motor Current Signature Analysis).

Some examples for typical errors:

- voltage fluctuations

- overtones/ harmonics

- rotor bar problems

- Mechanical overload

- Frequency converter problems

Periodic controls.

Motor failures and associated machine down times may be reduced by preventive maintenance. For this, inspections of electric motors are carried out in regular intervals. The Dynamic Motoranalyzer stores all test results, evaluates them and presents them as trend analysis. Based on the graphical and easily understandable trend development you can easily find out, if a motor´s condition is getting worse and avoid downtimes by purposeful maintenance.

A perfect supplement to the Dynamic MotorAnalyzer´s test results is the ombination with the test results of the electric motor testers MotorAnalyzer2 or surge voltage tester MTC2. The test results from the motor testers may be saved together with the Dynamic MotorAnalyzer´s test results in one data base and jointly evaluated for the trend analysis. Based on the combination of test methods, you receive an even deeper look in your electric motor´s condition or technical installations.

Your production´s availability and efficiency may be increased, as downtimes can cause costs of more than hundreds of thousands Euros per hour!

Thus, the aim of preventive maintenance is to avoid interruptions and unplanned downtimes.

Technology

All benefits at a glance.

- Power Quality Analysis

- Voltage per phase

- Fundamental oscillation and collective oscillation

- Phase-to-neutral -voltages -U1N – U2N – U3N : Uinstantaneous, Umin – Uaverage – Umax

- Phase conductor voltages-U12 – U23 – U31: Uinstantaneous, Umin – Uaverage – Umax

- Harmonics, up to the 50th harmonic

- THD – Total harmonic distortion

- HVF – Power reduction factor according to NEMA (National Electrical Manufacturers Association)

- CF – Crest factor

- Unbalance between the 3 phases

- Deviation to Unom

- NEMA Derating, American Association: National Electrical Manufacturers Association

- Frequency, min. – average – max.

- Phase angle between the 3 phases

- Voltage per phase

- Motor Quality Analysis

- Current per phase

- Fundamental oscillation and collective oscillation

- Motor current I1 – I2 – I3 : Iinstantaneous, Imin – Imittel – Imax

- Harmonics, up to the 50th harmonic

- THD – Total harmonic distortion

- CF – Crest factor

- Unbalance between the 3 phases

- Current harmonics

- Current´s frequency range

- Current per phase

- Motor Load Analysis

- Power measurement as:

- 1-Wattmeter-method

- 2-Wattmeter-method (Aron circuit) with conversion to 3-Wattmeter-method

- 3-Wattmeter-method

- Power per phase

- P – Active power

- S – Apparent power

- Q – Reactive power

- Unbalance between the 3 phases

- Overall power

- P – Active power, Pinstantaneous, Pmin – Paverage – Pmax

- S – Apparent power, Sinstantaneous, Smin – Saverage– Smax

- Q – Reactive power, Qinstantaneous, Qmin – Qaverage– Qmax

- Power harmonics

- Power´s frequency range

- cos φ, power factor PF

- Speed determination

- For this, an additional tachometer with laser sampling has to be ordered

- For this, also a DC-tachometer may be connected

- The speed is recorded even during long-time measurements

- Speed may also be entered manually

- Automatic speed determination from the motor´s current at asynchronous motors

- Speed measurement at motor shaft

- Torque

- Minimum value

-

maximum value

- minimum value

- Line recorder to display the torque´s temporary course/ torque monitoring

-

torque range

- torque ripple

-

- efficiency

- Power measurement as:

- Measuring inputs U + I

- 3 x 24 bit forU

- 3 x 24 bit for I

- Measuring rate 100 Ks

- plus free measuring inputs

- 6 x 12 bit for arbitrary signals

- e.g. tacho speed

- e.g. flow

- e.g. pressure

- e.g. vibration

- e.g temperature

- and more

- 6 x 12 bit for arbitrary signals

- Voltage measuring range

- Direct measurenent up to 700 Veff between outer conductors

- Indirect measurment via PTs up to 50 kV

- Current measuring range

- from 5 – 3.000 A

- Current measurement via CTs up to 10 kA

- Weight 3 kg

- Operating temperature 5 – 50° C

- Battery-operation

- Worldwide voltage supply 110 – 250 V / 47 – 63 Hz

Further facts.

- Voltage displayed analog/digital

- Current displayed analog/digital

- Direct 3-phase voltage measurement or via voltage transformers

- 3-phasige current measurement via current clamps, Rogowski clamps or current transformers

- Phase sequence indication in polar coordinates (U&I)

- Real time oscilloscope for mains analysis

- rms values – sine wave illustration (perfect for FU-analysis)

- U1N , U2N , U3N

- U12 , U23 , U31

- U1N – U2N – U3N -unbalance

- U12 – U23 – U31 -unbalance

- I1 , I2 , I3

- I1 , I2 , I3 -unbalance

- trigger for numerous events

- falling or rising trigger

- pre-trigger

- graphical oscillation as periodical illustration

- RMS-values (RMS) as from a line recorder

- Zoom function

- 2 x measuring markers to measure times and intervals

- 2 x measuring markers to measure voltages and voltage differences

- Unbalance-power reduction factor according to NEMA (National Electrical Manufacturers Association)

- Real time oscilloscope for motor analysis

- rms values – sine wave illustration (perfect for FU-analysis)

- U1N , U2N , U3N

- U12 , U23 , U31

- U1N – U2N – U3N -unbalance

- U12 – U23 – U31 -unbalance

- I1 , I2 , I3

- I1 , I2 , I3 -unbalance

- P1 , P2 , P3, Ptotal

- trigger for numerous events

- falling or rising trigger

- pre-trigger

- graphical oscillation as periodical illustration

- RMS-values (RMS) as from a line recorder

- Zoom function

- 2 x measuring markers to measure times and intervals

- 2 x measuring markers to measure voltages and voltage differences

- Unbalance-power reduction factor according to NEMA (National Electrical Manufacturers Association)

- Symmetrical components

- FFT up to 25 KHz

- linear, logarithmic or dB display

- Start-up transients

- triggering for a selectable phase

- trigger for numerous events

- falling or rising trigger

- pre-trigger, to also see the measured values before the event (look at “historical values”)

- start-up process

- triggering for a selectable phase

- falling or rising trigger

- pre-trigger

- Long-term recording

- triggering for a selectable phase, voltage or current

- triggering for one of the free measuring channels

- falling or rising trigger

- pre-trigger

- Phase-sequence correction possible, in case operator has created an incorrect connection

- 3-phasige current measurement via current clamps, Rogowski coils or current transformers

- current clamps with measuring range switchover

⇒ Find more details under Downloads.

For further information please do not hesitate to contact our technical sales under:

- +49 2372 901 25 40

- Email request

print preview

Product comparison

| type of tester |

| surge test |

| resistance |

| Induktivitäts-Kapazitätsprüfung |

| PE/GB |

| insulation |

| polarization index |

| high voltage AC |

| high voltage DC |

| partial discharge |

| function AC 1-phase |

| function AC 3-phase |

| sense of rotation |

| test terminals |

| test cover |

| automation |

| database |

| test plans |

| test results |

| communication |

| test report print-out |

| label print-out |

| scanner port |

| password protection |

| user management |

| operating system |

| display |

| battery mode |

| delivery |

|

|

|

|

|

|

|

|

|

|

|

| MTC2 R7 | MotorAnalyzer1 | MotorAnalyzer2 R2 | MTC2 | MTC3 | VoltageAnalyzer | GLP3-M | EncoderAnalyzer | Dynamic MotorAnalyzer | PortaTest | Winding Machines |

|

THE surge tester · normative partial discharge · resistance · 4 wire measurement · Windows 10|11® · test report · PDF printing · network … |

motor Service · repairs · troubleshooting · maintenance · servicing · battery operation · PC software … |

multitool · 15 test methods · surge voltage 3 kV · resistance · inductance · capacitance · motor service · repair · fault detection · maintenance · battery mode · PC software … |

THE surge tester – up to 50 kV – plus normative partial discharge – resistance – 4-wire measurement – Windows10® – test protocol – PDF printing – network … |

Uncompromising ALL-IN-1 winding test for production · for all standard and special motors · for automotive drives · for coils of all kinds · automation · in-line partial discharge testing – worldwide networking · central data storage … |

high-precision test probe – direct surge voltage measurement at the winding – partial discharge – passive / active microwave antenna – up to 6 kV … |

modular ALL-IN-1 engine test system · no limits · customer specific · VDE/EN/UL/IEC … · production · automation · global networking · databases · statistics · data import/export · Windows® · complex systems … |

encoder and resolver testing/adjustment · encoder signal analysis · encoder power supply: 3 – 30 V · interface: HIPERFACE – EnDat – SSI – BiSS · BEMF measurement · repair · motor service · encoder production · servo motor production … |

online monitoring · fault analysis on the running motor · for mains and frequency converters · over 100 measured values · speed · torque · efficiency · unique oscilloscope · data recorder · trend analysis · battery operation · outdoor … |

insulation oil testing ⋅ fully automatic ⋅ dielectric strength ⋅ mobile ⋅ portable ⋅ on-site testing ⋅ laboratory testing ⋅ test voltages: 60 kV – 80 kV – 100 kV ⋅ various electrodes ⋅ integrated international test standards … |

coil winding machines for electric motors · for repair · for motor production · standard machines · special solutions … |

| read more | read more | read more | read more | read more | read more | read more | read more | read more | read more | read more |

|

surge testers winding testers |

winding testers motor & winding testers ALL-IN-1 |

surge testers winding testers motor & winding testers ALL-IN-1 |

surge testers winding testers |

surge testers winding testers |

— | electric motor testers ALL-IN-1 | encoder/resolver testers | electric motor testers ALL-IN-1 | insulating oil testers | winding machines |

|

0–6 kV 0–12 kV 0–15 kV |

— | 0–3 kV |

0–6 kV 0–12 kV 0–15 kV 0–25 kV 0–30 kV 0–40 kV 0–50 kV |

0–6 kV 0–15 kV |

0–6 kV | 0–6 kV | — | — | — | — |

| 4-wire measurement | 4-wire measurement | 4-wire measurement | 4-wire measurement | 4-wire measurement | — | 4-wire measurement | — | — | — | — |

|

nein ja |

— | — | — | — | — | — | — | — | — | — |

| — | — | — | — |

1–10 A˜ 6/12 Veff 1–30 A˜ 6/12 Veff |

— |

1–10 A˜ 6/12 Veff 1–30 A˜ 6/12 Veff custom |

— | — | — | — |

| Vmax like surge test | 0–3 kV ˭ | 0–6 kV ˭ | Vmax like surge test | Vmax like surge test | — |

0–1 kV ˭ max. 250 GΩ custom |

— | — | — | — |

| Vmax like surge test | Vmax like insulation test | Vmax like insulation test | Vmax like surge test | Vmax like surge test | — | — | — | — | — | — |

| 0–6 kV˜ max. 100 mA | — | — | 0–6 kV˜ max. 100 mA |

0–3 kV˜ max. 100 mA 0–6 kV˜ max. 100 mA 0–6 kV˜ max. 200 mA 0–6 kV˜ max. 1 A custom |

— |

0–3 kV˜ max. 100 mA 0–6 kV˜ max. 100 mA 0–6 kV˜ max. 200 mA custom |

— | — | — | — |

| 0–4 kV ˭ | 0–6 kV ˭ | — | custom | — | — | — | — | |||

| in case of surge test | — | — | in case of surge test |

in case of surge test in case of high voltage test AC in case of surge voltage and high voltage |

in case of surge test |

in case of surge test in case of high voltage test AC in case of surge voltage and high voltage |

— | — | — | — |

| — | — | — | — | — | — | according to your requirements | — | — | — | — |

| — | — | — | — | — | — | according to your requirements | — | according to your requirements | — | — |

| yes | yes | yes | yes | yes | — | yes | — | — | — | — |

|

T1, T2, T3, frame T1, T2, T3, Y, frame K1, K2, frame |

T1, T2, T3, frame | T1, T2, T3, frame |

T1, T2, T3, frame T1, T2, T3, Y, frame K1, K2, frame |

T1, T2, T3, frame T1, T2, T3, Y, frame 3, 6, 9, 12, 15, 18, ..., frame |

T1, T2, T3 |

L1, L2, L3, N, PE made to your specifications |

— | — | — | — |

| possible | — | — | possible | possible | — | possible | — | — | — | — |

|

with digital I/O with RS232 via SCHLEICH communication protocol with LAN via SCHLEICH communication protocol |

— | — |

with digital I/O with RS232 via SCHLEICH communication protocol with LAN via SCHLEICH communication protocol |

with digital I/O with RS232 via SCHLEICH communication protocol with LAN via SCHLEICH communication protocol with LAN via TCP/IP Socket Communication with PROFIBUS with PROFINET with EtherCAT with DeviceNet made to your specifications |

— |

with digital I/O with RS232 via SCHLEICH communication protocol with LAN via SCHLEICH communication protocol with LAN via SCPI commands with PROFIBUS with PROFINET with EtherCAT with CANopen with CAN Automotive with DeviceNet made to your specifications |

— | — | — | — |

|

ACCESS SQL |

— | — |

ACCESS SQL |

ACCESS SQL |

— |

ACCESS SQL ORACLE |

— | — | — | — |

|

stored in the tester stored in the tester and network import from PC, PLC, MES, ... |

— | — |

stored in the tester stored in the tester and network import from PC, PLC, MES, ... |

stored in the tester stored in the tester and network import from PC, PLC, MES, ... |

— |

stored in the tester stored in the tester and network import from PC, PLC, MES, ... |

— | — | — | — |

|

cached in the tester or network transfer to PC, PLC, MES, ... |

cached in the tester | cached in the tester |

cached in the tester or network transfer to PC, PLC, MES, ... |

cached in the tester or network transfer to PC, PLC, MES, ... |

— |

cached in the tester cached in the tester or network transfer to PC, PLC, MES, ... |

— | — | — | — |

|

with ERP, MES, PLC, CAQ, ... via LAN, WWW, OPC, ... |

— | — |

with ERP, MES, PLC, CAQ, ... via LAN, WWW, OPC, ... |

with ERP, MES, PLC, CAQ, ... via LAN, WWW, OPC, ... |

— |

with ERP, MES, PLC, CAQ, ... via LAN, WWW, OPC, ... |

— | — | — | — |

| yes | yes - via PC-Software | yes - via PC-Software | yes | yes | — | yes | — | yes | — | — |

| yes | — | — | yes | yes | — | yes | — | — | — | — |

| yes | — | — | yes | yes | — | yes | — | — | — | — |

| yes | — | yes | yes | yes | — | yes | — | yes | — | — |

| yes | — | — | yes | yes | — | yes | — | yes | — | — |

| Windows 10 11®-PC in the tester | SCHLEICH embedded | SCHLEICH embedded | Windows 10®-PC in the tester | Windows 10®-19"-Industrial PC integrated | — | Windows 10®-19"-Industrial PC integrated | — | Windows 10®-PC in the tester | — | — |

| PC monitor of any size | LCD 120 x 80 | touch color LCD 480 x 272 | PC monitor of any size | PC monitor of any size | — | PC monitor of any size | — | — | — | — |

| — | yes | yes | — | — | — | — | — | yes | — | — |

| on stock | on stock | on stock | on stock | order-related manufacturing | order-related manufacturing | order-related manufacturing | order-related manufacturing | order-related manufacturing | order-related manufacturing | order-related manufacturing |

SCHLEICH is a leading manufacturer of electrical safety, functional, winding and electric motor testing technology.

SCHLEICH is a world-renowned company that focuses on the development of innovative products in the field of testing technology for electrical products of all kinds.

From A to Z - everywhere SCHLEICH testing technology is in use worldwide. Our customers come from over 50 countries and regions. Everything is developed and produced in Germany.

Quality work - Made in Germany.

2022 - SCHLEICH is awarded for the fifth time as TOP100-Innovator

2016 - SCHLEICH released the first VoltageAnalyzer for measuring the real voltage directly at the winding terminals

2012 - SCHLEICH is awarded as TOP100-Innovator for the first time

2005 - SCHLEICH released the first stator tester with partial discharge test

1995 - SCHLEICH integrates touch-displays into testing devices as a world leader

1990 - SCHLEICH released the first safety and function tester with fully automatic integrated test terminal changeover

1987 - SCHLEICH released the first surge tester with PC-control under DOS and fully automatic integrated test terminal changeover

1985 - SCHLEICH released the first MotorAnalyzer

1982 - SCHLEICH focuses fully on electrical test engineering of electrical products

1952 - SCHLEICH is founded as a motor repair shop

Pioneering spirit, competence, curiosity, brand new technologies and innovations. This is what the 145-strong SCHLEICH team stands for - led by Martin & Jan-Philipp Lahrmann. Father & son. Your guarantors for long-term partnership.