The expert level tester for your motor service

Compact design and a wide range of applications for troubleshooting in windings that are not live are the distinguishing features of MotorAnalyzer2 R2.

15 elaborate tests and test methods are built in, including surge voltage tests up to 3 kV. Due to its integrated lithium-ion battery, tests can also be performed off-grid without a power connection.

MotorAnalyzer2 R2 is the ultimate ALL-IN-ONE tester for electrical engineering, motor repair, maintenance and servicing.

No other portable tester for this scope of application offers such a wide range of support for fault detection and servicing in motors and generators.

| Types of faults | SCHLEICH All in 1 tester MotorAnalyzer2 |

other „all in one“ tester |

Megohmmeter Insulation tester | DMM Multimeter |

|

| Open connection | |||||

| Short to housing | |||||

| Short between phases | |||||

| Short between turns | |||||

| Winding faults | |||||

| Connecting faults | |||||

| Insulation faults | |||||

| Contamination | |||||

| Stator faults | |||||

| Rotor faults | |||||

| Coils faults | |||||

| Temperature sensor fault | |||||

| Test methods | |||||

| Insulation resistance | 6 kV | 500 GΩ | ||||

| Polarization index PI | |||||

| Dielectric Absorption DAR | |||||

| Surge test | 3 kV | ||||

| Resistance test | 100 μΩ – 500 kΩ | 4W | ||||

| 4 wire meausurement | Kelvin clamps | ||||

| Temperature compensation | resistance & insulation | ||||

| Inductance | 10 μH – 1500 H | ||||

| Impedance | 1 mΩ – 500 kΩ | ||||

| RIC-Test | |||||

| Phase symmetry | |||||

| Capacitance | 10 nF – 50 μF | ||||

| Stator rotating field | |||||

| Motor rotating field | |||||

| Additional functions | |||||

| Fault location in the slot | |||||

| Neutral zone adjustment | |||||

| Conclusion | TOP ALL in 1 |

restricted | critical | unsuitable |

The universal tool.

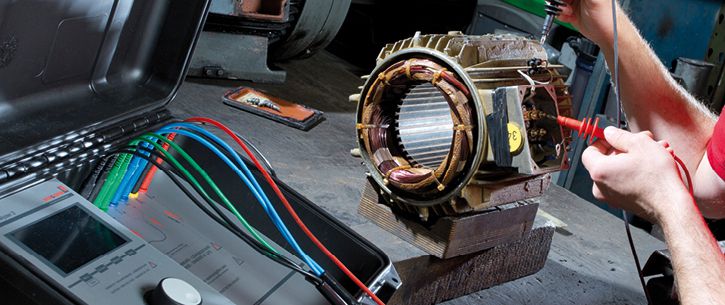

The versatile MotorAnalyzer2 R2 was designed for testing electric motors and windings. It combines 15 different test methods in a single user-friendly and portable device. The combination of test methods, its exceptionally compact design and optional battery mode operation make MotorAnalyzer2 R2 an excellent tool for on-site use – especially in difficult mounting locations.

To check an AC motor, the three winding leads and the motor frame are connected to the tester. For high-precision resistance measurement it is best to use 4-wire measurement. MotorAnalyzer2 R2 automatically starts the surge voltage, resistance, inductance and high-voltage tests one after the other. The internal relay matrix automatically switches the different test methods in sequence to the four measuring points.

In addition to motor testing, MotorAnalyzer2 R2 also assists in adjusting the brush of a DC motor (neutral zone adjustment) and for fault location of the two slots in which the coil with the turn-to-turn fault is located.

MotorAnalyzer2 R2 is mounted in a very compact, sturdy and waterproof transport case. Next to the control panel you can find a storage compartment for all measuring cables and test probes. At on-site measurements the operator always has all necessary equipment at hand quickly.

Harder mechanical use can optionally be absorbed with a case plus integrated shock absorber concept.

| MotorAnalyzer without [SHOCK PROTECTION] – |

MotorAnalyzer with [SHOCK PROTECTION] – |

|

|

| – | |

|

|

| The inner case can be lifted out. This means that the MotorAnalyzer2 R2 can also be used without the protective case. – |

|

|

|

|

|

Autotest

Surge voltage

Resistance

Inductance

RIC-Test (Rotor Influence Check) – squirrel cage rotor test

Impedance

High voltage DC

Polarization index & DAR

Insulation resistance

PE/GB-resistance

Capacitance

Neutral Zone adjustment for DC motors

Rotary Field of the stator

Sense of rotation of the motor

Locating the slots with Turn-to-Turn fault

Power Supply

⇒ Find more details in PDF brochures under Downloads.

Testing a motor with the fully automated Autotest or directly with single test methods.

High-voltage test of a stator with test probes to find faults to frame and phase-to-phase faults.

Resistance test, moving from bar to bar with 4-wire test probes.

Turn-to-turn fault detection of a stator with a test probe, moved from slot to slot through the entire stator.

A typical example of an application in incoming goods: the autotest shows the defects at a glance

Für weitergehende Informationen steht Ihnen unser technischer Vertrieb auch gerne telefonisch zur Verfügung.