Do I feel safe?

Am I doing everything right?

You will know for sure in a few minutes.

Safety tests are mandatory and are part of every final inspection of your electrical product.

Learn the most important facts about the protective earth test.

We explain the WHY?, WHERE?, HOW? and also the WHEN NOT!

And if you would like to learn more, you can download even more detailed information at the end of this page free of charge!

WHY?

The protective conductor is the central protective measure to ensure electrical safety. It ensures that in the event of a defect, no dangerous voltage is present on the housing of the equipment. Because if it did occur, a life-threatening current could flow through the user if the housing was touched!

The protective conductor should therefore at least reduce and in the best cases even completely eliminate the danger to persons.

But of course it has to work perfectly for that! And you have to prove and document this in a test before delivery of your electrical product.

The protective conductor resistance test is a routine test. This means that for every piece, i.e. every single electrical product you put on the market, a protective earth resistance test must be carried out.

WHERE?

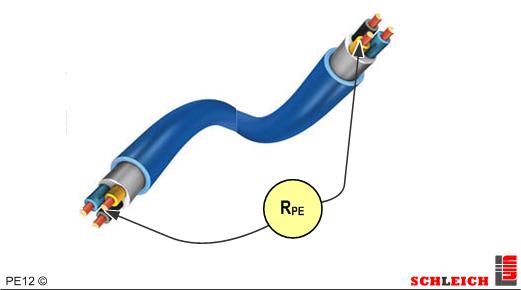

The most critical defect is a total short circuit between a phase and an electrically conductive part of the equipment’s housing. If a user now touches the housing, a life-threatening electric shock could result. This must be avoided! To do this, you must connect all electrically conductive parts of the housing safely to the central protective conductor.

In the worst case, the protective conductor must be able to discharge a full short circuit between the phase and a conductive part of the housing to earth. The very high short-circuit current flows – and continues to flow until a fuse trips and the equipment is de-energized.

During this time, no excessive contact voltage may be generated on any part of the housing. However, this could happen if the resistance of the protective conductor is too high. The result would be an excessive dangerous voltage drop at the protective conductor.

Therefore all internal and external protective conductor connections must be checked for perfect performance. This is done either by manually scanning the housing parts using a test probe. Or, if all individual housing parts are connected to the test device by test leads, fully automated.

HOW?

In order to simulate the high current load on the protective conductor as realistically as possible, the protective conductor test is therefore performed with a high test current.

The evaluation criterion for the test is the ohmic resistance. It must not be too high, as otherwise the contact voltage on the equipment will be too high in the event of damage.

The upper limit of the protective conductor resistance can be defined differently from product to product and in different regions/continents. Therefore, you must take the test parameters from the standard applicable to the product and region.

| Test paramters | typical norm values | SCHLEICH | from standard to customized |

| maximum permissive PE resistance | 100 – 200 – 500 mΩ | from 0.0001 to > 10 Ω |

| Minimum test current required | 10 – 30 A (AC or DC) 200 mA (e.g. VDE 0113, 701, 702) |

from 0.1 to > 100 A (AC or DC) |

| maximum allowable test voltage | 6/12 V 6 – 24 V (e.g. VDE 0113) |

from 6 to > 24 V |

| minimum test time | 1 s | from 1 s to 24 h |

With this range of requirements, it is of course ideal to use a test device that covers as many of the world’s standards as possible.

That is SCHLEICH’s strength.

WHEN NOT?

Electrical products of protection class II have a reinforced or double housing insulation. The housing does have electrically conductive components – but these cannot be live due to the design. Such products are therefore electrically safe to touch by virtue of their construction. They therefore do not require a protective conductor. Thus, no protective earth resistance test is possible or necessary.

All set? Want more details?

Our mission – know-how, know-how, know-how… Those who understand the test methods with technical and normative certainty will get the most out of their test device.

– Dipl. Ing. Martin Lahrmann

Yes – tell me more. I want maximum security for our customers, our company and myself.

Send me more detailed information from the SCHLEICH test method handbook.

HandHeld

PE-resistance and insulation resistance tester- protective conductor resistance test up to 10 A AC

- insulation resistance test up to 1,000 V

- mobile – lightweight – indoor/outdoor

- transport case – carrying strap

- PC software

- attractive acquisition costs …

- hospital service

- rotor blade lightning protection test on wind turbines …

GLP1-g

PE conductor, insulation, high voltage and function testing deviceThe smallest safety tester in the world!

- PE/GB-resistance testers

- insulation resistance testers – IR

- high voltage testers AC/DC

- safety & function testers

- 50+ device configurations – combining up to 9 test methods in one device

- PLe, SIL3, Kat4 safety circuit (depending on device variant and degree of risk)

- table-top unit or 19″ rack mounting

- ½ 19″ or 19″ format

GLP2-BASIC

Protective conductor, insulation, high voltage, leakage current and function tester- insulation Resistance testers – IR

- high voltage testers AC/DC

- “All in one” testers

- safety & function testers

- app. 40 device variants – combined from up to 21 test methods

- PLe, SIL3, Kat4 safety circuit (depending on device variant and degree of risk)

- network

- protocol & label printing

- scanner …

- Technology Package for even more ergonomics

- table-top unit or 19″ rack mounting

GLP2-MODULAR

Combination tester with up to 25 test methods- “All in one”

- safety testers

- safety & function testers

- modular combination of more than 25 test methods possible

- up to 250 test connections

- large switch matrix modules for all kind test methods

- PLe, SIL3, Kat4 Safety circuit (depending on device variant and degree of risk)

- network

- protocol & label printing

- scanner …

- Technology Package for even more ergonomics

GLP3

Unlimited class leading test technology.The TOP-Class of testing and measuring technology for safety and functional testing.

- “All in one”

- safety & function testers

- for complex projects

- for complex automation

- for the highest demands

- modular combination of more than 30 test methods

- up to 350 test connections

- large switch matrix modules for all kind test methods

- PLe, SIL3, Kat4 safety circuit

- Windows 10®

- network

- protocol & label printing

- industry 4.0

- interfaces to MES, ERP, SPS …