Test Method

Ohmic Resistance

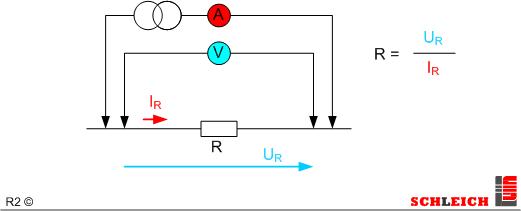

The resistance test serves to measure the resistance and for a later evaluation.

The evaluation is carried out by comparing the measured value with a set value and the corresponding tolerance.

The resistance test is no safety-relevant test, but is only used for checking function and quality.

For automatic evaluation the resistance set point and the permissible tolerance is given.

In contrast to the continuity test, even smallest resistances may be determined and evaluated.

Depending from the tester, the smallest resistances are measured in the μΩ- range.

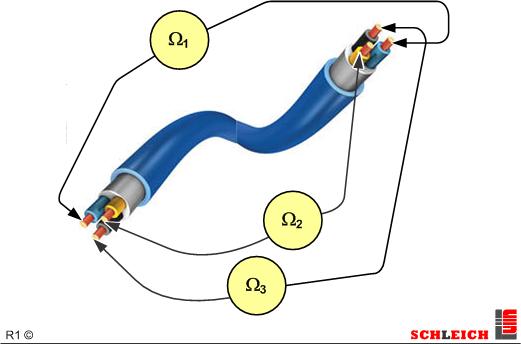

4-wire-technology is used to be able to measure these small resistances without the unfluence of measuring lead- or contact resistances.

Only this way resistances in the μΩ range may be measured.

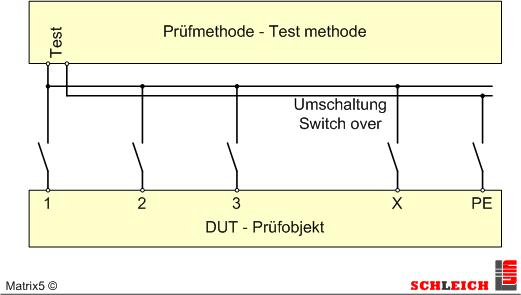

It is also possible to build fully-automatic testers with extensive matrixes (switch-over fields) for the automatic testing at several test points. There is almost no limitation for the amount of matrix points.

Easy switchover to test from different test points against a central test point, e.g. for testing PE.

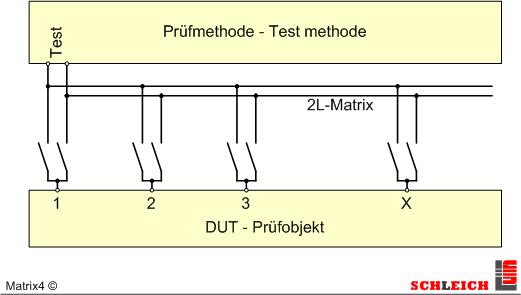

2-wire matrix, to test any test points “anyone against anyone”.

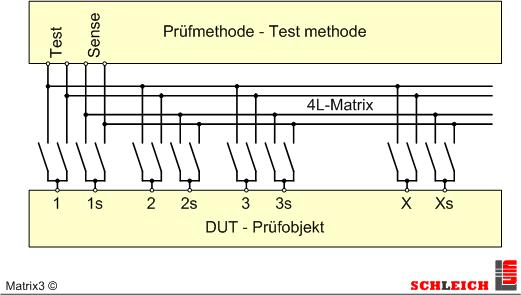

4-wire matrix to test any test points “anyone against anyone”.

A combination with other test methods is no problem.

The measuring is extremely fast. This is one of many extraordinary features of the test equipment made by SCHLEICH.

Standards commitees

For legal reasons, we can often not make a binding statement about the test conditions. For the application, the currently valid standards for testing your product apply.

Depending on the geographical location of the product, the standards to be applied can vary. For further information, please also refer to the below-mentioned bodies.

![]()

![]()

![]()

![]()

![]()