Test Method

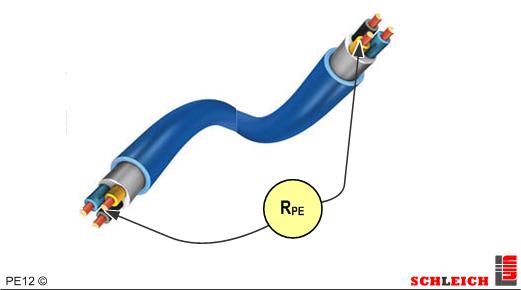

ground bond

The PE test is performed at devices of protection class I.

It is checked, whether the PE resistance is below a limit value defined in the standards. The test is to detect whether possible leakage currents inside the test object are grounded correctly. If the PE connection is not OK, this could result into a too high touch voltage at exposed metallic parts of the device. If these metallic parts were touched, the so-called touch current could run through the person to ground.

It is also possible that later, when operating the device, the insulation inside the device gets worse. This could lead to a short-circuit between the current-carrying leads and the enclosure of the device. Through the short-circuit, the enclosure would be under voltage. In the worst case, this type of fault could lead to the enclosure being under mains voltage. If now anybody touches the device, this would bear a great risk. By generating a short-circuit against ground, the PE is supposed to protect the person. The generated short-circuit current must reliably be discharged by the PE against ground.

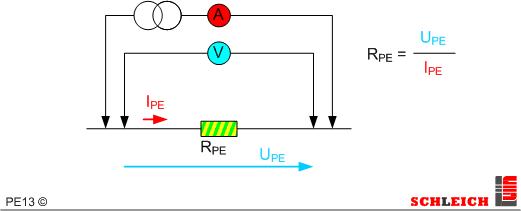

To detect the PE resistance, a test current determined in the standards is lead through the PE. The level of the test current is normally at least 1.5 times the nominal current of the device. The maximum current level, however, is limited to 25A … 100A. In the United States of America and Canada the test currents can be higher. The test current produces a voltage drop at the PE, which is measured. With the level of the test current and the voltage drop, the PE resistance is calculated.

In order to have a test result independent from the length of the test lead, the PE test is performed in 4-wire configuration.

The 4-wire configuration requires 2 leads for leading the high test current through the resistor and 2 leads for measuring the voltage drop at the resistor.

PE tests are often performed at several PE test points by manually contacting the test points with a PE test probe.

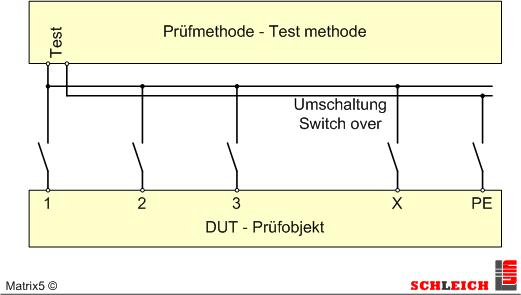

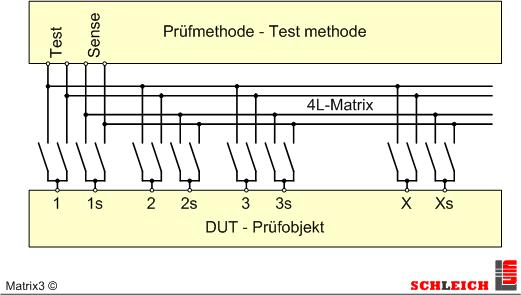

It is also possible to set up fully-automatic testers with extensive matrixes (switch-over fields) for the automatic testing at several PE test points. There is almost no limitation for the amount of matrix points.

Simple switching to test from different test points against a central test point, e.g. the PE

4-wire matrix to check between any test points according to the procedure “everyone against everyone″.

Which testers does SCHLEICH supply?

- single testers

- combination testers (combination with safety tests)

- Different versions in the range of 10 TΩ

- manual tests via test probes

- fully automatic tests

- matrixes with up to 500 clamps and fully-automatic switchover

- various tester classes

Standard committees

For legal reasons, in many cases, we cannot make an obligatory statement about the test conditions. Important for the application is the currently valid standard for your product to be tested.

Depending on the geographical location of the product, the standards to be applied can vary. For further information, please refer to the following institutes.

![]()

![]()

![]()

![]()

![]()