Test Method

Electrical continuity

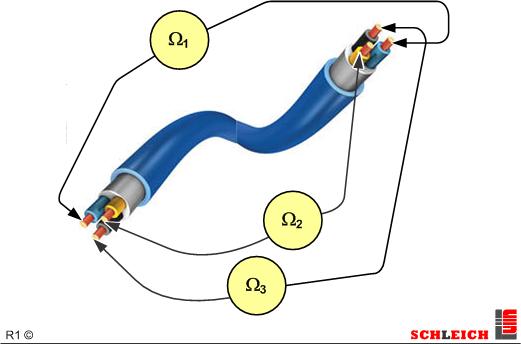

The continuity test serves to measure the continuity based on resistance and for a later evaluation.

The evaluation is carried out by comparing the measured value with a set value and the corresponding tolerance.

The continuity test is no safety-relevant test, but is only used for checking function and quality.

For the automatic evaluation the resistance set value and the permissible +/- tolerance is predefined.

The continuity test is not able to precisely measure and evaluate small resistances as it is not carried our in 4-wire technology. In case low continuity resistances between 1-10Ω are to be measured with high accuracy, the precise 4-wire resistance measurement is recommended instead.

Standards commitees

For legal reasons, we can often not make a binding statement about the test conditions. For the application, the currently valid standards for testing your product apply.

Depending on the geographical location of the product, the standards to be applied can vary. For further information, please also refer to the below-mentioned bodies.

![]()

![]()

![]()

![]()

![]()