What does this mean for the electrical engineering industry, service companies and maintenance engineers?

Since the beginning of November 2019, the new standard must be observed during the repair, overhaul and refurbishment of rotating electrical machines.

The standard now defines very precisely which work is to be carried out, especially from the point of view of testing technology. Also the how is described with many details. We are not allowed to publish passages of the standard here. However, it is advisable to purchase the standard in any case, e.g. from Beuth (publishing company) .

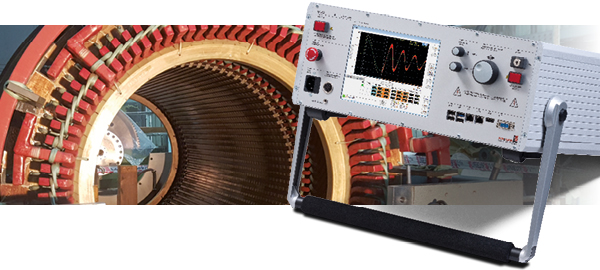

SCHLEICH has the suitable testing technology for the described test specifications!

MotorAnalyzer2 R2 – THE All-in-one-tester

14 different test methods for testing electric motors, generators and windings in one mobile device.

- automatic stator/motor analysis – clamp windings and housing – the rest is done fully automatically

- automatic switching between the four test lines

- surge voltage up to 3 kV

- precision resistance measurement in four-wire technology with temperature compensation

- continuity check

- inductance measurement with advantageous high test current

- impedance measurement

- RIC test for testing the squirrel cage

- capacity measurement

- insulation resistance up to 6 kV DC with temperature compensation

- polarization index PI & DAR up to 6 kV DC with temperature compensation

- manual high voltage up to 6 kV DC

- test probe for the detection of a short circuit

- rotary field test of the winding and the motor

- setting aid for the neutral zone on direct current machines

- battery or mains operation

- printout of the test results via a PC

- …

MTC2 – the deep look into the winding

The surge voltage tester of the upper class – with convincing performance diversity.

- digital surge voltage test 6 kV – 50 kV

- standard-compliant partial discharge test

- impact energy up to 125 Joule

- surge current up to 2000 A

- rise time up to 60 ns

- …

Dynamic-MotorAnalyzer – perfect in every detail

The device for troubleshooting and condition monitoring on running motors and generators.

- measurements on the running engine – also for dynamometers

- for mains and frequency converter operation

- for all tests such as voltage, frequency, harmonics, THD, HVF, current, electrical and mechanical power, speed, torque, efficiency

- …

The best for last.

The test instruments MotorAnalyzer1, MotorAnalyzer2 R2 and partly also the MTC2 are available from stock!

Please send us your inquiry.

MotorAnalyzer1

The entry-level device for your motor serviceCheck your motor’s health!

- induction, synchronous and DC motors, brakes, transformers, coils …

- repair, service, maintenance, servicing

- 10 test methods in one device

- troubleshooting and fault location

- adjusting the neutral zone on DC motors

- light and portable

- battery operation

- PC software for printing and saving

MotorAnalyzer2 R2

The expert level tester for your motor serviceCheck your motor’s health!

- asynchronous, synchronous and direct current machines, brakes, transformers, coils …

- repair, service, maintenance, servicing

- ALL-IN-ONE – 15 test methods in one device

- surge voltage test up to 3 kV !

- high voltage DC and insulation up to 6 kV

- resistance, inductance, impedance, capacitance, RIC test

- troubleshooting and fault location

- adjusting the neutral zone on DC motors

- light and portable

- battery or mains operation

- PC software for printing and saving

MTC2

Surge tester with 6, 12, 15, 25, 30, 40 or 50 kVThe state of the art winding tester.

- surge test plus standard-compliant partial discharge measurement

- resistance

- insulation resistance

- high voltage DC plus polarization index / DAR

- high voltage AC

ideal for service, production, automation, quality control, laboratory, R&D …

Dynamic MotorAnalyzer

Check your motor's health!Troubleshooting & online condition monitoring of running motors/generators.

What is the cause of the problem?

The Dynamic MotorAnalyzer supports troubleshooting and analysis.

- suitable for mains and frequency inverter operation

- electrical mains and motor input data

- energy consumption, capacity utilisation, efficiency …

- mechanical power and torque …

- unique multifunctional oscilloscope

- data recorder for long-term measurements

- data recorder for real-time measurement data and playback for later analysis

- trend analysis for predictive maintenance

EncoderAnalyzer

Inspecting and adjusting encoders- detailed encoder signal analysis

- resolver

- hall element encoder

- incremental encoder, sinue/cosine encoder

- absolute encoder (singleturn and multiturn)

- communication via Hiperface, EnDat, SSi, BiSS …

- measurement of incorrect angle of rotor and encoder angle on synchronous motor

- support of manual angle adjustment

- setting the encoder zero point

- writing the misaligned angle into the encoder

- synchronous motor test

- measurement of the BEMF

- determination of the ke-value during motor ramp down